Precision Investment Casting Equipment

The Foundation of Complex Metal Parts

In industries demanding micron-level accuracy, precision investment casting equipment is the cornerstone of success. At KEWEI, we engineer cutting-edge machines designed to produce high-tolerance (±0.05mm), defect-free castings for aerospace, medical, and automotive applications.

Why Precision Matters in Investment Casting

- Complex Geometries: Achieve intricate designs with thin walls and fine details.

- Material Integrity: Minimize porosity and inclusions for superior mechanical properties.

- Cost Efficiency: Reduce post-processing and scrap rates.

- Industry Compliance: Meet stringent standards (e.g., AS9100 for aerospace).

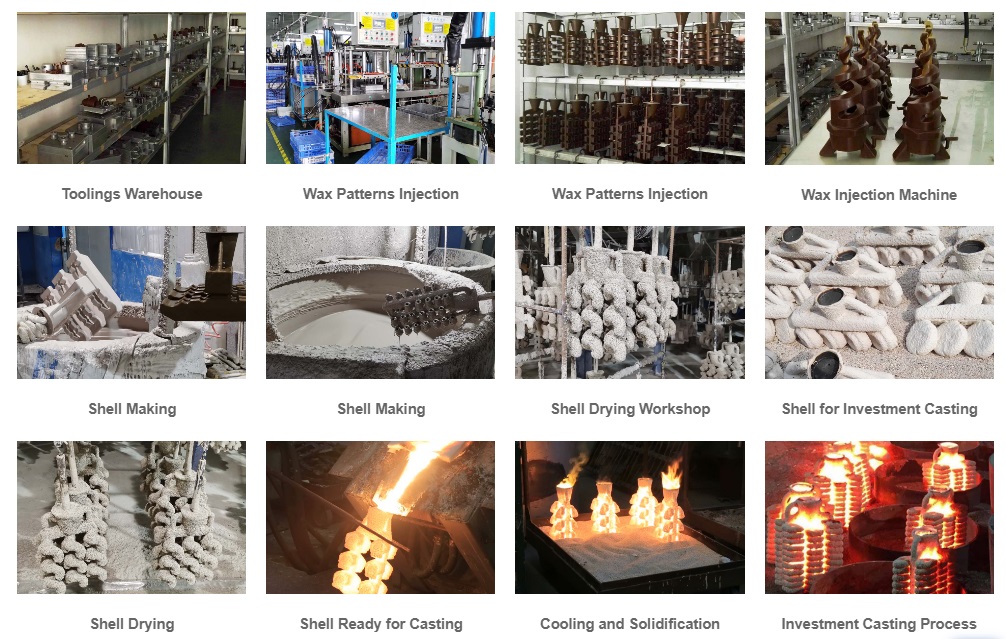

KEWEI’s Core Precision Investment Casting Equipment

- High-Precision Wax Injection Machines

- Function: Create flawless wax patterns with ±0.03mm tolerance.

- KEWEI Advantage: Temperature-controlled molds and IoT-enabled monitoring.

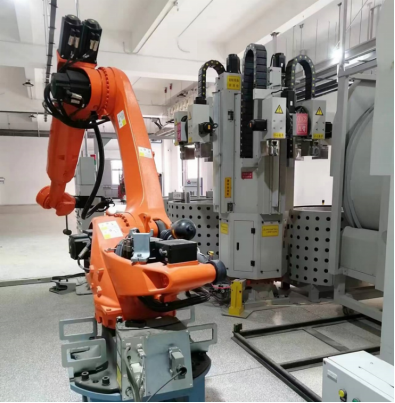

- Automated Ceramic Shell Coating Systems

- Function: Apply uniform ceramic layers for defect-free shells.

- KEWEI Advantage: Robotic slurry dipping with real-time viscosity control.

- Vacuum Casting Units

- Function: Pour molten metal under vacuum for porosity-free castings.

- KEWEI Advantage: Vacuum levels ≤30mbar, ideal for titanium and superalloys.

- CNC Machining Centers

- Function: Precision finishing of cast parts to final dimensions.

- KEWEI Advantage: 5-axis machining with ±0.01mm accuracy.

Applications of KEWEI’s Precision Equipment

- Aerospace: Turbine blades, fuel nozzles, and engine housings.

- Medical: Biocompatible implants and surgical tools.

- Automotive: Lightweight EV components with tight tolerances.

- Energy: High-temperature alloy parts for turbines.

Why Choose KEWEI: Our equipment is trusted by industry leaders for delivering mission-critical components with unmatched precision.

Benefits of Choosing KEWEI’s Precision Equipment

- Ultra-High Accuracy: Achieve tolerances as tight as ±0.05mm.

- Advanced Automation: Reduce human error with AI-driven process control.

- Material Flexibility: Cast stainless steel, titanium, Inconel®, and more.

- Scalability: From prototypes to mass production, adapt to any demand.

FAQs About Precision Investment Casting Equipment

Q: How does KEWEI ensure equipment precision?

A: Our machines integrate laser calibration, real-time sensors, and closed-loop control systems.

Q: Can KEWEI’s equipment handle small-batch production?

A: Yes! We offer flexible solutions for both low-volume and high-volume needs.

Q: What support does KEWEI provide after purchase?

A: Installation, operator training, maintenance plans, and 24/7 technical support.

Ready to Achieve Micron-Level Precision with KEWEI?

✅ Free Consultation: Get expert advice tailored to your needs.

✅ Competitive Quotes: Compare prices from top suppliers.

✅ Fast Delivery: Minimize downtime with quick shipping.