Military Investment Casting Equipments

Mission-Critical Precision for Defense & Aerospace

In the defense sector, where failure is not an option, military investment casting Equipments demands uncompromising precision, material integrity, and traceability. KEWEI, a globally certified supplier to NATO and allied forces, specializes in military-grade investment casting for mission-critical components in aerospace, armored vehicles, and naval systems. With ITAR-compliant processes and AS9100/NADCAP certifications, discover how KEWEI empowers defense OEMs to meet the highest standards of performance and security.

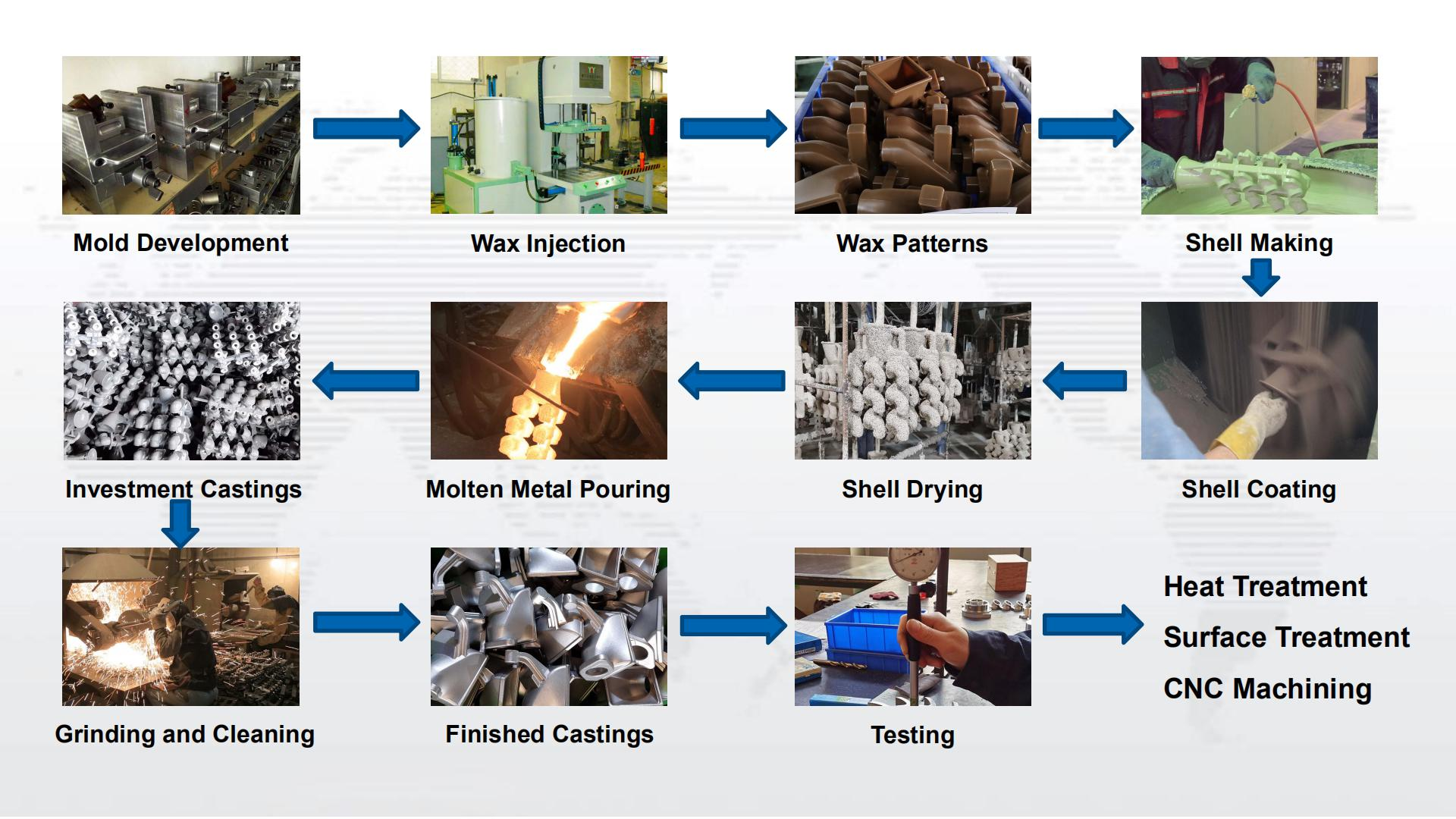

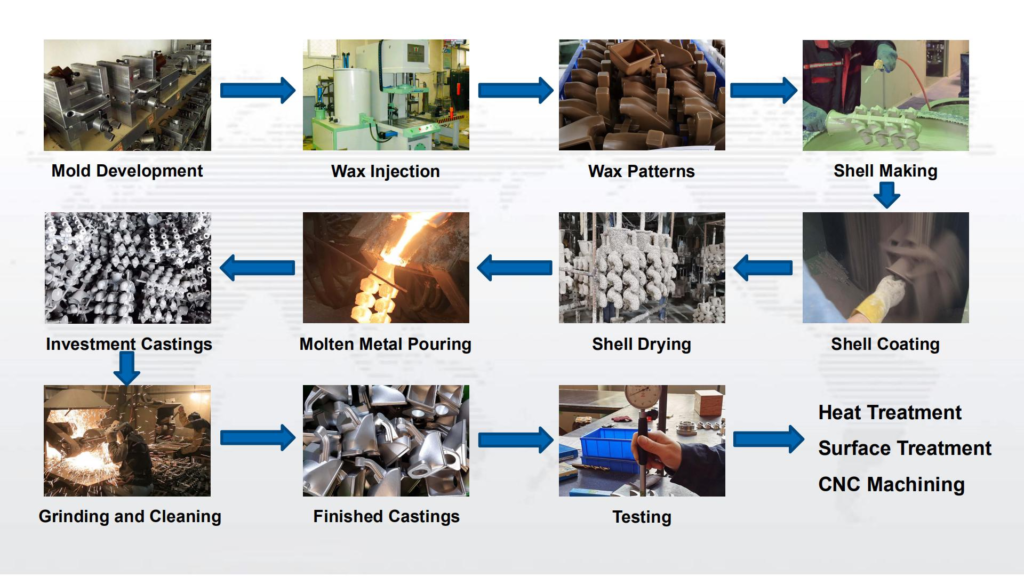

1. The Rigors of Military Investment Casting

Military applications require components that withstand extreme conditions:

- Ballistic Resilience: Armor plating and weapon systems with MIL-STD-1942 compliance.

- High-Temp Performance: Turbine blades for fighter jets (Inconel 718, Rene alloys).

- Corrosion Resistance: Submarine valves and naval hardware for saltwater environments.

KEWEI’s Edge: Proprietary ceramic shell molds and vacuum melting ensure 100% defect-free castings per MIL-I-23011A.

Related Keywords: defense investment casting, military-grade casting solutions

2. KEWEI’s Military-Specific Capabilities

KEWEI’s military investment casting systems are engineered for defense readiness:

- ITAR Compliance: Secure data protocols and restricted access facilities.

- Advanced NDT Testing: X-ray, ultrasonic, and dye penetrant inspection per MIL-STD-271.

- Rapid Prototyping: 10-day turnaround for classified R&D projects.

Case Study: A NATO-approved supplier achieved 30% weight reduction in armored vehicle components using KEWEI’s titanium casting solutions.

Related Keywords: aerospace investment casting, ITAR-compliant foundry

3. Critical Defense Applications

KEWEI produces components for:

- Aerospace: Turbine blades, missile guidance housings (MIL-DTL-5002).

- Ground Systems: Lightweight armor, suspension parts for tanks and APCs.

- Naval: Corrosion-resistant pump impellers and sonar housings.

Related Keywords: military metal casting, defense casting components

4. Overcoming Military Casting Challenges

- Supply Chain Security? KEWEI’s vertically integrated production ensures end-to-end control.

- Material Traceability? Blockchain-enabled lot tracking from raw alloy to finished part.

- Cybersecurity Risks? ISO 27001-certified digital infrastructure.

Related Keywords: defense manufacturing solutions, secure casting processes

5. Partnering with KEWEI: Beyond Compliance

Choosing KEWEI unlocks:

- Classified Project Support: Secure facilities for ITAR/EAR-controlled components.

- Multi-Stage Validation: First Article Inspection (FAI) per AS9102 and PPAP.

- Global Logistics: Expedited shipping with MIL-SPEC packaging.

Related Keywords: military casting supplier, defense industry foundry.

Conclusion

In an era of evolving threats and technological asymmetries, KEWEI military investment casting equipments provides the precision, durability, and security demanded by global defense ecosystems. With 20+ years of certified expertise and a zero-defect mandate, we are the trusted partner for mission-success-critical components. Ready to Armor Your Supply Chain? Contact KEWEI for a Secure Consultation today.