Casting Foam Mixer

The lost foam casting foam mixer features a three-dimensional barrel with a cantilever shaft supported by a triangular or bracket structure at the base. Key components such as the motor, drive box, and cantilever bearing are designed to avoid contact with viscous materials, ensuring smooth operation and longevity.

A unique stirring paddle guarantees thorough and even mixing by driving viscous material near the container walls downward, while material in the center moves upward. Internal anti-adhesion baffles further enhance the flow of viscous substances, preventing buildup. The standard stirring drive box provides stable performance and simplifies maintenance.

The paint stirring equipment (lost foam casting foam mix) from Kewei incorporates a double-bearing structure, enabling high-standard, uniform mixing. It is ideal for blending low-viscosity liquids, particularly for EPC coating applications, as well as preparing other casting and architectural coatings.

Kewei’s Lost Foam Casting line advantages

- High Precision: Achieves exceptional accuracy in casting, ensuring that components meet stringent specifications.

- Excellent Surface Quality: Delivers superior surface finishes, reducing the need for additional processing.

- Environmental Sustainability: Operates with no emissions or waste, making it an eco-friendly choice in metal casting.

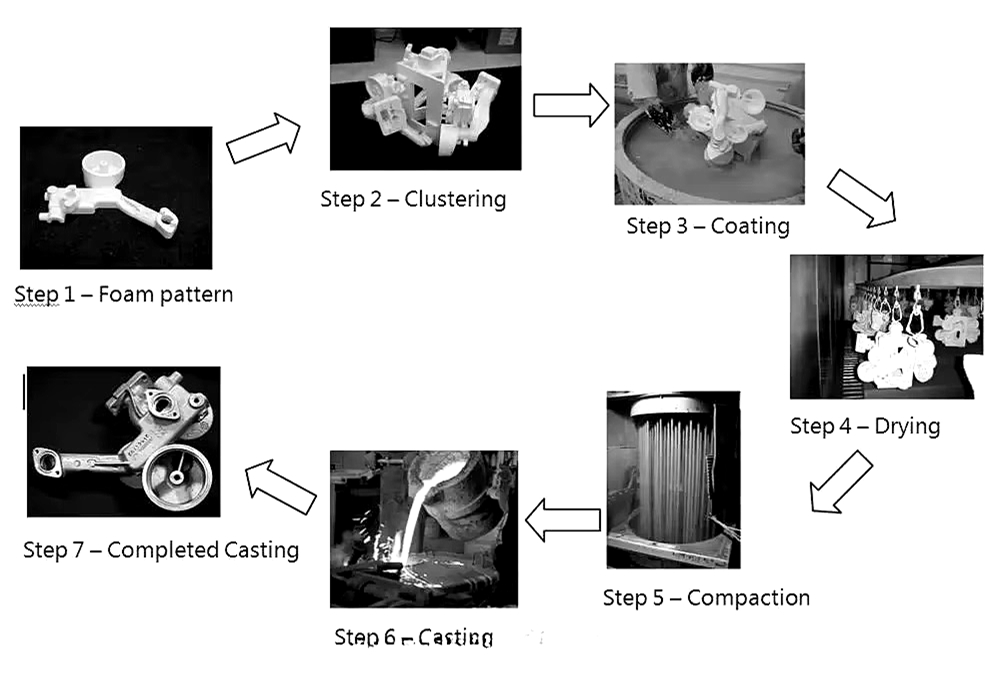

Features of Lost Foam Casting

- High Casting Quality at Low Cost:

The process delivers excellent casting quality while maintaining cost-effectiveness. - Material Versatility:

There are no significant material limitations, allowing for a range of suitable sizes. - Precision and Surface Finish:

Achieves high precision and a smooth surface finish, reducing the need for extensive cleaning and saving on machining time. - Reduced Internal Defects:

Significantly minimizes internal defects, resulting in a compact casting structure. - Large-Scale Mass Production:

Capable of supporting large-scale and mass production of components. - Ideal for Repeated Castings:

Particularly suitable for the mass production of identical castings. - Flexible Operation:

Adaptable for both manual operation and automated production line control. - Environmental Compliance:

The production line’s operational status meets environmental protection technical parameters. - Improved Working Conditions:

Enhances the working environment and production conditions in the casting line, reducing labor intensity and energy consumption.

These features collectively position lost foam casting as a highly efficient and sustainable option in the manufacturing of complex castings.