KEWEI Investment Casting Tooling Cost

Introduction

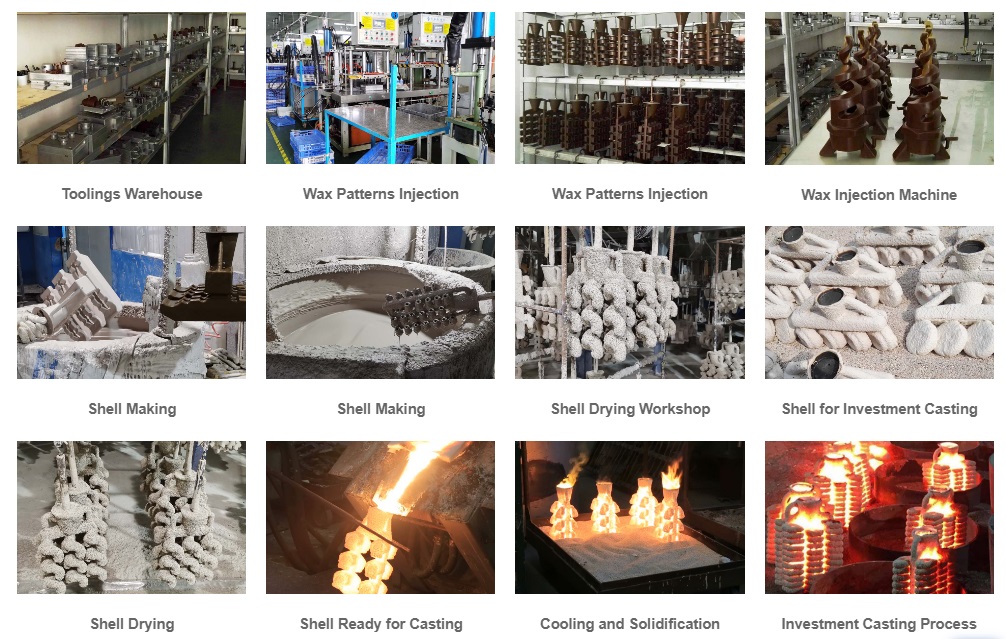

In the precision-driven world of investment casting, tooling costs—encompassing mold design, materials, and maintenance—can make or break profitability. KEWEI, a global leader in cost-efficient foundry solutions, combines advanced engineering, material science, and smart automation to help aerospace, automotive, and medical manufacturers reduce investment casting tooling costs by up to 40% while maintaining zero-defect standards. Discover how KEWEI transforms tooling from a cost center to a competitive advantage.

1. Key Factors Driving Investment Casting Tooling Costs

Understanding cost drivers is the first step to optimization:

- Mold Complexity: Intricate geometries increase CAD/CAM programming and machining time.

- Material Selection: High-performance ceramics vs. cost-effective alternatives.

- Production Volume: Low-volume vs. high-volume tooling strategies.

- Maintenance & Lifespan: Frequent repairs vs. durable, long-lasting molds.

KEWEI Insight: Our AI-driven simulation tools reduce design iterations by 50%, slashing upfront engineering costs.

Related Keywords: casting tooling expenses, mold design costs

2. KEWEI’s Proven Strategies to Reduce Tooling Costs

A. Smart Design Optimization

- Generative AI Design: Automate mold geometry for minimal material use and maximum durability.

- Modular Tooling: Reusable components cut per-unit costs by 15-25%.

B. Material Innovation

- High-Durability Ceramics: KEWEI’s proprietary blends extend mold lifespan by 3X vs. industry averages.

- Cost-Effective Alternatives: Silica-alumina mixes for non-critical applications without sacrificing quality.

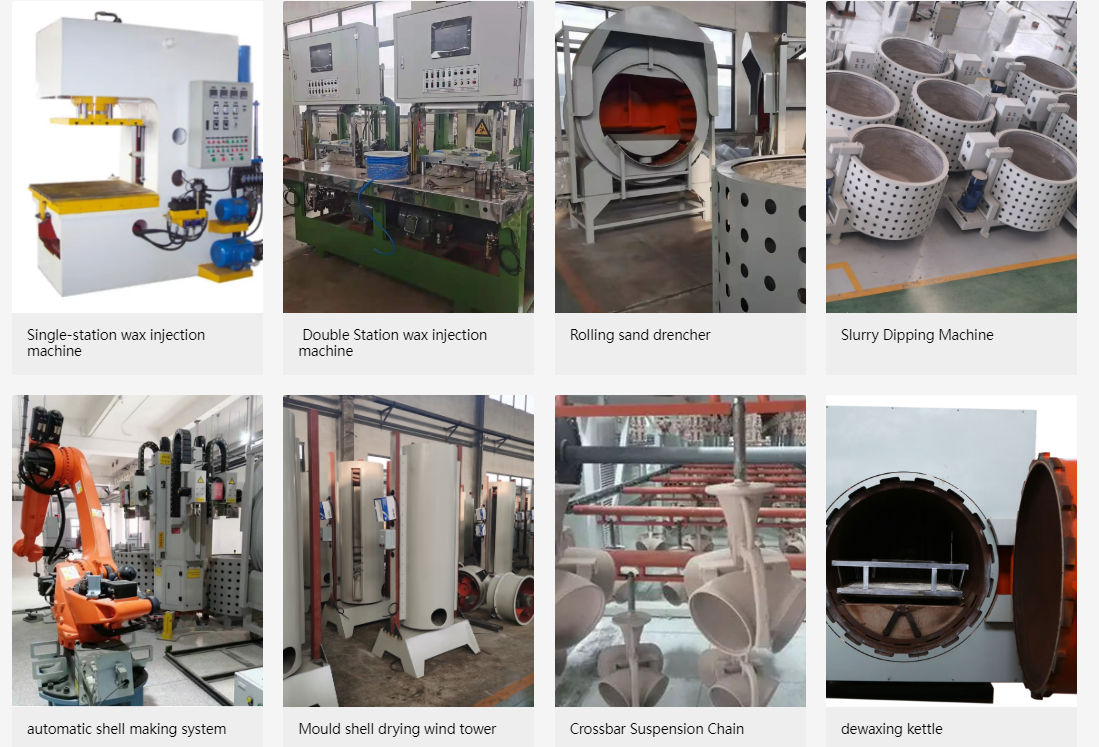

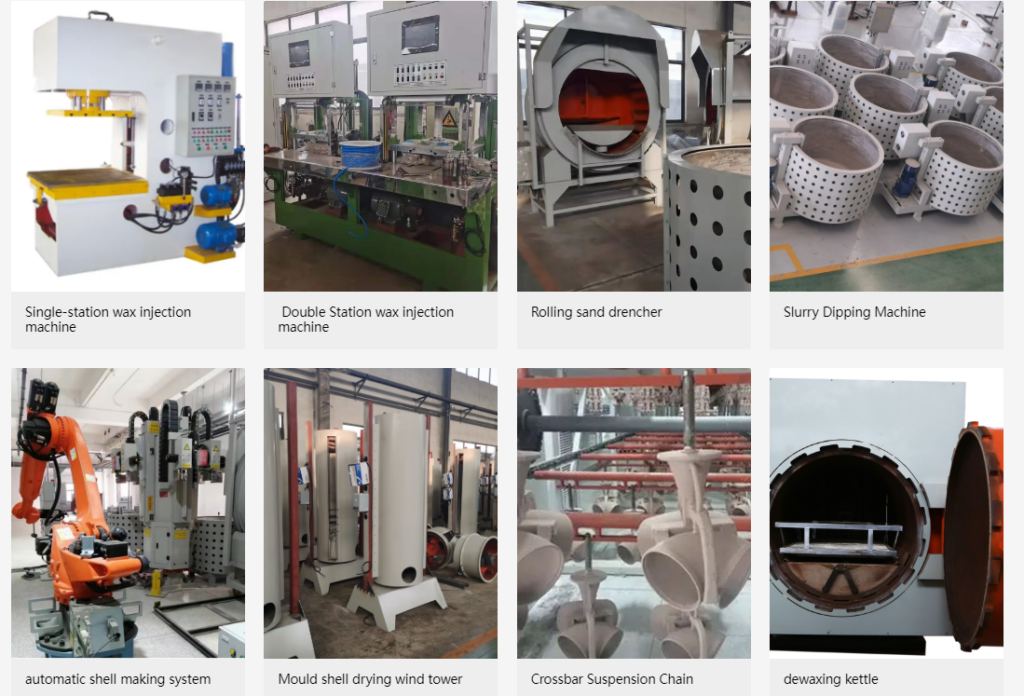

C. Automation & Scalability

- 3D-Printed Wax Patterns: Eliminate costly CNC machining for complex prototypes.

- IoT-Enabled Maintenance: Predictive analytics reduce unplanned downtime by 30%.

Related Keywords: reduce tooling expenses, durable casting molds

3. Case Study: Slashing Costs for an Automotive Client

Challenge: A Tier-1 supplier faced 35% tooling cost overruns on aluminum EV battery housings.

KEWEI Solution:

- Redesigned molds using topology optimization (25% less material).

- Implemented modular tooling for 5 product variants.

- Integrated robotic shell coating to extend mold life.

Result: 28% lower tooling costs and 18% faster time-to-market.

Related Keywords: investment casting cost reduction, automotive tooling solutions

4. Hidden Costs to Avoid in Tooling Investment

- Over-Engineering: Avoid overspecifying tolerances beyond functional requirements.

- Poor Supplier Selection: Low upfront quotes may hide frequent maintenance costs.

- Manual Processes: Labor-intensive mold finishing inflates long-term expenses.

KEWEI’s Fix: Our Total Cost of Ownership (TCO) calculator provides transparent 5-year cost projections.

Related Keywords: tooling lifecycle costs, casting mold TCO

5. Why Partner with KEWEI for Cost-Effective Tooling?

- Rapid Prototyping: Test mold designs in 7 days, avoiding costly late-stage changes.

- Global Material Sourcing: Leverage KEWEI’s partnerships for 20% lower ceramic prices.

-

Free Cost-Benefit Analysis: Benchmark your current tooling spend against industry standards.

Related Keywords: low-cost investment casting tooling, KEWEI mold engineering

Conclusion

Investment casting tooling costs need not be a barrier to profitability. With KEWEI’s data-driven design, durable materials, and smart automation, manufacturers achieve 30-40% cost savings while maintaining ISO 9001 and AS9100 quality standards. From prototype to mass production, KEWEI delivers the precision and efficiency your bottom line demands.

Ready to Revolutionize Your Tooling Economics?

Contact KEWEI Today for a Free Tooling Cost Audit!