Investment Casting Robots

Revolutionizing Precision & Efficiency

Introduction

In the high-stakes world of investment casting, precision and repeatability are non-negotiable. KEWEI (formerly KW Casting), a global innovator in smart foundry solutions, pioneers investment casting robots that redefine automation for aerospace, automotive, and medical industries. From robotic pouring to post-casting finishing, discover how KEWEI’s AI-driven robotics eliminate human error and elevate production benchmarks.

1. The Role of Robots in Modern Investment Casting

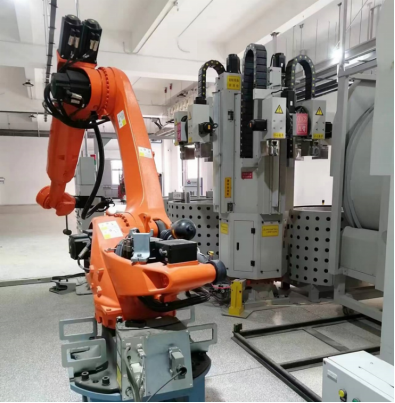

Investment casting robots automate critical processes:

- Robotic Pouring: 6-axis arms with ±0.05mm repeatability for defect-free fills.

- Shell Coating: Uniform ceramic slurry application via programmable paths.

- Deburring & Finishing: Force-controlled grinding for complex geometries.

Related Keywords: automated casting robots, robotic pouring systems, foundry automation

2. KEWEI’s Robotic Technology: Why It Leads

KEWEI’s investment casting robots integrate breakthrough innovations:

- AI Vision Systems: Detect mold defects in real-time with 99.9% accuracy.

- High-Temperature Resilience: Operate in 50°C+ environments with ceramic fiber shielding.

- Seamless Integration: Compatible with KEWEI furnaces and heat treatment lines.

Case Study: An automotive client reduced cycle time by 35% and scrap rates by 18% using KEWEI’s robotic shell coating system.

Related Keywords: KEWEI robotic pouring, intelligent casting automation

3. Industry-Specific Robotic Solutions

KEWEI tailors robots to your needs:

- Aerospace: Vacuum-compatible robots for superalloy turbine blade handling.

- Medical: Cleanroom-certified robots for titanium implant finishing.

- Energy: Heavy-duty robots for large valve casting extraction.

Related Keywords: robotic investment casting, automated shell coating

4. Solving Critical Production Challenges

- Labor Shortages? Robots handle 24/7 operations with zero fatigue.

- Inconsistent Quality? Machine learning adapts to mold variations.

- High Costs? ROI achieved in <12 months via waste reduction and uptime.

Related Keywords: investment casting labor costs, robotic process optimization

5. Partnering with KEWEI: Beyond Hardware

Choosing KEWEI unlocks:

- Free Workflow Analysis: Digitally map your process for automation opportunities.

- Virtual Training: AR-guided tutorials for operator upskilling.

- Global Support: 24/7 remote diagnostics and spare parts logistics.

Related Keywords: investment casting robot supplier, smart foundry solutions

Conclusion

The future of investment casting is intelligent, automated, and data-driven. With KEWEI’s robotics—backed by ISO 10218 safety certifications and 15+ years of industry expertise—your foundry can slash costs, boost throughput, and dominate competitive markets. Ready to Embrace Industry 4.0? Contact KEWEI for a Free Robotic Cell Simulation!

Lost Wax Casting Investment Powder

Engineered for Precision & Durability

Introduction

In the lost wax casting process, the investment powder is the unsung hero that determines mold strength, surface finish, and defect-free metal components. KEWEI (formerly KW Casting), a global leader in advanced casting materials, formulates lost wax casting investment powders trusted by aerospace, medical, and automotive manufacturers. Discover how KEWEI’s proprietary blends elevate your ceramic shell molds to new heights of precision.

1. What is Lost Wax Casting Investment Powder?

Investment powder is a refractory material blend used to create ceramic shell molds in lost wax casting. KEWEI’s powders combine:

- High-Purity Components: Alumina, zircon, and fused silica for thermal stability up to 1700°C.

- Advanced Binders: Colloidal silica and ethyl silicate for rapid curing and crack resistance.

- Nano-Additives: Reduce gas porosity by 50% through optimized particle gradation.

Related Keywords: ceramic shell investment powder, refractory coating material, precision casting slurry

2. Why KEWEI’s Investment Powder Outperforms

KEWEI’s R&D-driven formulations deliver:

- 30% Faster Drying: Accelerate production without compromising mold strength.

- Zero Shell Delamination: Patented adhesion promoters ensure layer bonding.

- ECO Compliance: REACH-certified, low-VOC powders for sustainable manufacturing.

Case Study: A turbine blade manufacturer reduced shell cracking by 95% using KEWEI’s zircon-based investment powder.

Related Keywords: KEWEI ceramic shell materials, investment powder supplier

3. Industry-Specific Formulations

KEWEI tailors powders to your application:

- Aerospace: Ultra-high-temperature blends for nickel superalloys (e.g., Inconel 718).

- Medical: Bio-inert powders for titanium and cobalt-chrome implants.

- Automotive: Cost-efficient silica-alumina mixes for high-volume aluminum parts.

Related Keywords: custom investment powder, lost wax casting materials

4. Solving Common Powder-Related Challenges

- Mold Cracking? KEWEI’s optimized thermal expansion coefficients prevent stress fractures.

- Surface Roughness? Sub-micron particle sizing ensures mirror-like finishes.

- Material Waste? Precision slurry recycling systems reduce powder usage by 20%.

Related Keywords: ceramic shell defects, investment powder optimization

5. Partnering with KEWEI: Beyond Material Supply

Choosing KEWEI provides:

- Free Slurry Analysis: Audit your current mix and receive a performance upgrade plan.

- Just-in-Time Delivery: Global logistics ensure emergency orders within 48 hours.

- Technical Support: On-site engineers troubleshoot slurry preparation and coating.

Related Keywords: lost wax casting powder supplier, ceramic shell solutions

Conclusion

The right lost wax casting investment powder is the foundation of precision, efficiency, and cost control. With KEWEI’s ISO 9001-certified formulations, cutting-edge R&D, and industry-proven expertise, your foundry can achieve zero-defect castings and dominate competitive markets. Ready to Elevate Your Shell Molds? Request a Free Sample of KEWEI’s Investment Powder Today!