KEWEI Investment Casting Production Line

Precision, Speed & Scalability Redefined

Introduction

In the competitive landscape of precision manufacturing, an optimized investment casting production line is the difference between mediocrity and market leadership. KEWEI, a global ISO 9001-certified innovator, delivers fully integrated investment casting production lines that combine robotic automation, AI-driven process control, and decades of metallurgical expertise. Trusted by aerospace, automotive, and medical industries, KEWEI’s turnkey solutions empower foundries to achieve zero-defect output, 30% faster cycle times, and scalable growth.

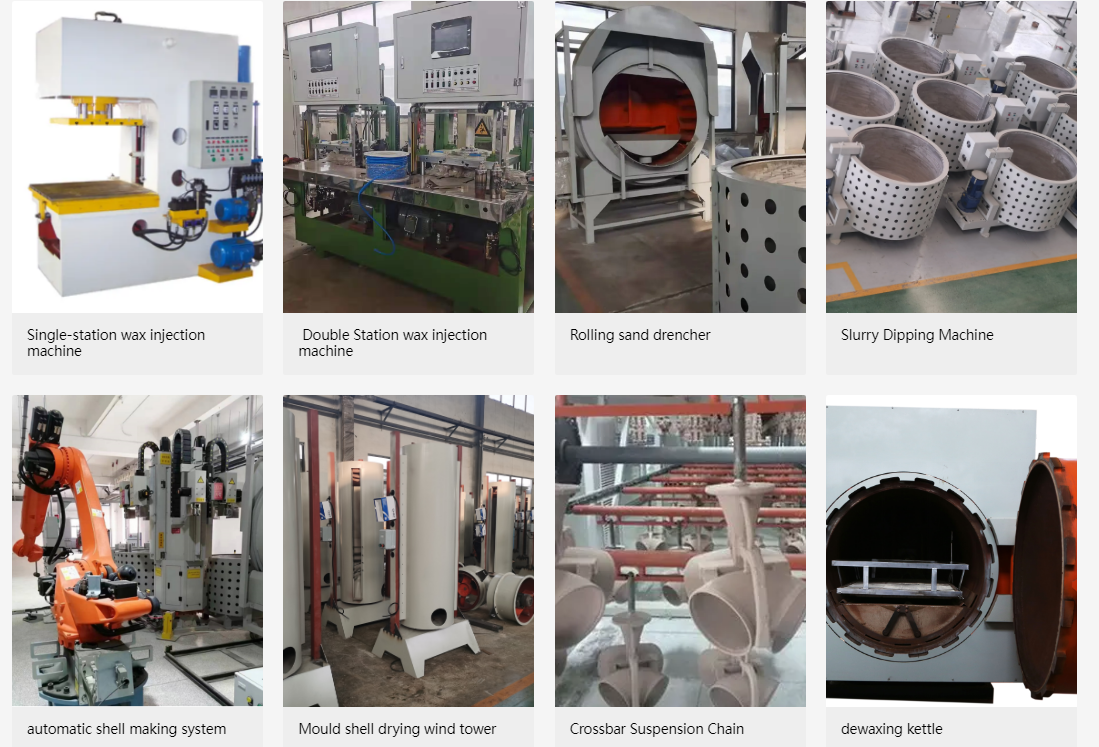

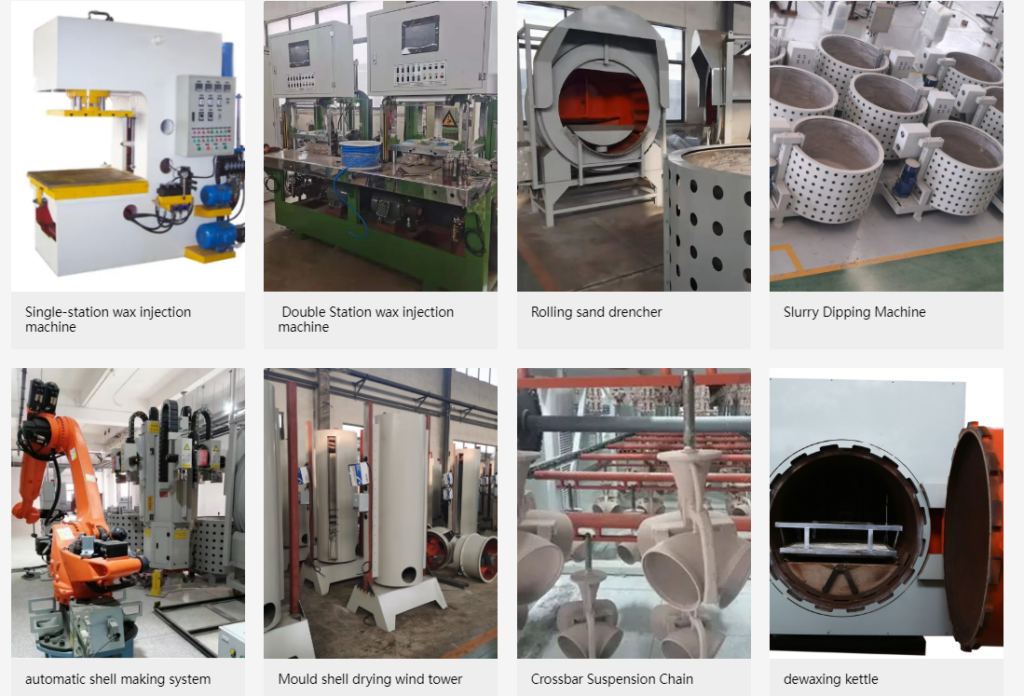

1. Core Components of KEWEI’s Production Line

KEWEI’s investment casting production line integrates every critical stage into a seamless workflow:

A. Advanced Wax Pattern Systems

- 3D-Printed Wax Models: Achieve ±0.05mm tolerances for complex geometries.

- Automated Wax Injection: 20% faster cycle times with AI-controlled temperature/pressure.

B. Ceramic Shell Automation

- Robotic Slurry Coating: 6-axis arms ensure uniform shell thickness (0.1mm variance).

- AI-Powered Drying: Predictive algorithms optimize humidity and airflow.

C. Melting & Pouring Solutions

- Vacuum Induction Furnaces: Melt superalloys up to 1800°C with ±3°C stability.

- Smart Tilt Pouring: IoT-enabled robots eliminate turbulence-induced defects.

D. Post-Casting Excellence

- Automated Knockout Stations: Remove shells 50% faster with minimal part damage.

- CNC Finishing Cells: Achieve medical-grade surface finishes (Ra <0.8μm).

Related Keywords: automated casting production line, end-to-end foundry solutions

2. Why KEWEI’s Production Line Dominates

KEWEI’s investment casting production lines solve industry-wide challenges:

- Zero Human Error: Robotics handle 95% of repetitive tasks, ensuring consistency.

- Energy Efficiency: Regenerative burners cut furnace energy use by 25%.

- Scalable Output: Modular designs support 100 to 10,000+ units/month.

Case Study: A medical implant manufacturer doubled throughput and reduced scrap by 28% with KEWEI’s fully automated line.

Related Keywords: KEWEI foundry automation, smart investment casting line

3. Industry-Specific Configurations

KEWEI tailors production lines for mission-critical applications:

- Aerospace: Vacuum-compatible lines for NASA/MSFC-spec turbine blades.

- Automotive: High-speed lines for aluminum EV components (IATF 16949 certified).

- Energy: Corrosion-resistant lines for offshore valve production (API 6A compliant).

Related Keywords: custom casting production line, industrial foundry systems

4. Overcoming Production Line Challenges

- High Labor Costs? KEWEI’s robotics reduce workforce needs by 60%.

- Quality Inconsistency? Machine learning adapts to material batch variations.

- Slow ROI? Achieve breakeven in <18 months via waste reduction.

Related Keywords: investment casting line optimization, foundry cost control

5. Partnering with KEWEI: Beyond Machinery

Choosing KEWEI unlocks unparalleled value:

- Free Line Design: Our engineers map your workflow for maximum efficiency.

- Smart Factory Integration: Sync production data with ERP/MES via OPC-UA.

- Lifetime Support: 24/7 remote diagnostics and spare parts hubs in 15 countries.

Related Keywords: investment casting line supplier, turnkey foundry solutions

Conclusion

In an era where agility and precision define industrial success, KEWEI investment casting production lines deliver the technological backbone to dominate global markets. With 20+ years of innovation, vertically integrated manufacturing, and a relentless focus on client ROI, KEWEI empowers foundries to transform raw metal into high-margin components—faster, cleaner, and smarter. Ready to Lead Your Industry? Contact KEWEI for a Free Production Line Simulation Today!