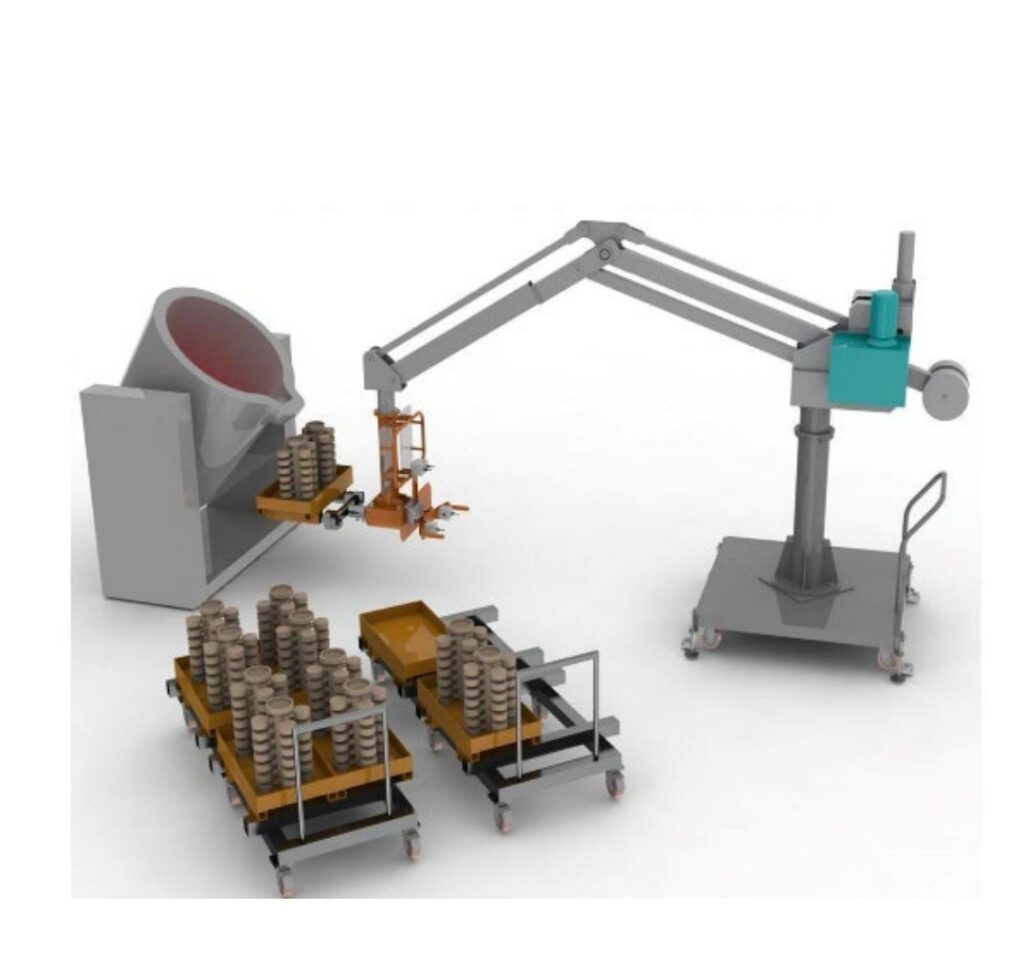

Investment Casting Pouring machine

Precision Control for Flawless Metal Components

In investment casting, the pouring process—where molten metal fills the ceramic shell mold—is a defining moment that determines component integrity, surface finish, and dimensional accuracy. KEWEI (formerly KW Casting), a global leader in precision casting solutions, engineers investment casting pouring machine that combine advanced automation, temperature control, and decades of metallurgical expertise. Discover how KEWEI’s pouring technology ensures perfection for aerospace, medical, and automotive industries.

1. The Science of Investment Casting Pouring

KEWEI’s pouring process optimizes three critical factors:

- Temperature Control: Maintain molten metal within ±10°C of target (e.g., 1550°C for stainless steel).

- Flow Dynamics: Laminar filling prevents turbulence-induced inclusions.

- Solidification Management: Directional cooling minimizes shrinkage porosity.

Related Keywords: precision metal pouring, vacuum casting pouring, molten metal flow

2. KEWEI’s Investment Casting Pouring machine: Why It Leads

KEWEI’s investment casting pouring systems solve industry challenges with:

- Automated Tilt Pouring: 6-axis robots ensure consistent angle and speed, reducing human error.

- Real-Time Monitoring: Infrared sensors track metal temperature and mold preheat status.

- Material Versatility: Pour everything from aluminum (660°C) to cobalt-chrome alloys (1500°C+).

Case Study: A medical implant manufacturer achieved 99.5% defect-free titanium castings using KEWEI’s vacuum pouring system.

Related Keywords: KEWEI tilt pouring, investment casting automation

3. Industry-Tailored Pouring Solutions

KEWEI adapts pouring methods to your needs:

- Aerospace: Vacuum-assisted pouring for nickel superalloy turbine blades.

- Automotive: High-speed gravity pouring for aluminum EV components.

Related Keywords: vacuum investment casting, centrifugal pouring systems

4. Overcoming Common Pouring Defects

- Gas Porosity? KEWEI’s degassing systems reduce hydrogen levels to <1.5 ppm.

- Cold Shuts? AI-driven preheating ensures mold temperatures >800°C.

- Oxidation? Argon shielding protects melts during transfer.

Related Keywords: investment casting defects, metal pouring optimization

5. Partnering with KEWEI: Beyond Equipment

Choosing KEWEI unlocks:

- Free Process Audit: Identify inefficiencies in your current pouring workflow.

- Smart Factory Integration: IoT-enabled systems sync pouring with upstream/downstream processes.

- Global Compliance: Systems meet AS9100 (aerospace) and ISO 13485 (medical) standards.

Related Keywords: investment casting pouring services, foundry automation solutions

Conclusion

Precision investment casting pouring is the bridge between molten metal and high-performance components. With KEWEI’s cutting-edge robotics, sensor-driven controls, and industry-specific expertise, your foundry can eliminate defects, reduce waste, and exceed customer specifications. Ready to Perfect Your Pour? Contact KEWEI for a Free Process Simulation!