KEWEI Investment Casting Injection Moulding

Precision Wax Patterns for Complex Components

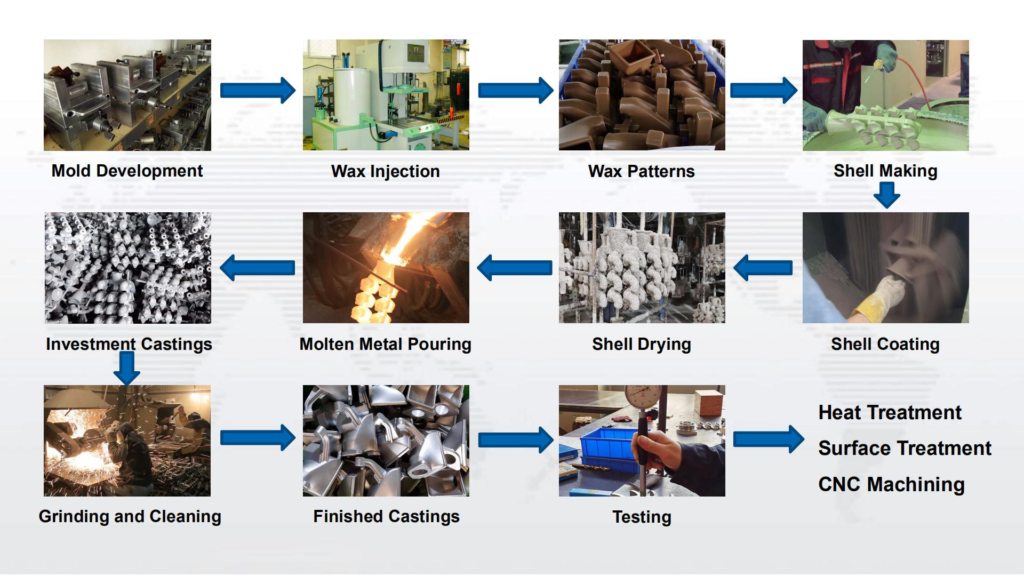

In investment casting, injection moulding is the critical first step to creating precise wax patterns for intricate metal components. KEWEI, a global ISO 9001 and AS9100-certified leader, pioneers injection moulding systemsthat integrate AI-driven automation, advanced materials, and decades of expertise. Trusted by aerospace, medical, and automotive industries, KEWEI’s technology ensures defect-free wax patterns, reduces cycle times by 40%, and slashes material waste by 30%. Discover how KEWEI redefines precision in the casting workflow.

1. The Role of Injection Moulding in Investment Casting

KEWEI’s injection moulding process transforms wax into high-accuracy patterns through:

- AI-Optimized Parameters: Real-time control of temperature (65–85°C) and pressure (±0.5 bar) to eliminate flow lines.

- Multi-Cavity Moulds: Produce 8–12 wax patterns simultaneously, boosting throughput by 50%.

- Low-Shrinkage Waxes: Proprietary blends ensure ±0.05mm dimensional stability post-cooling.

Related Keywords: wax injection moulding, precision casting moulds

2. KEWEI’s Injection Moulding Technology: Key Innovations

A. Smart Automation

- Self-Learning Algorithms: Adjust injection parameters based on mould geometry and ambient conditions.

- IoT-Enabled Machines: Sync with ERP systems for real-time production tracking and predictive maintenance.

B. Material & Design Excellence

- Eco-Friendly Waxes: REACH-compliant formulations reduce VOC emissions by 45%.

- Modular Moulds: Rapidly reconfigure for new designs (72-hour turnaround).

Case Study: An aerospace client achieved 99.8% defect-free wax patterns for turbine blades using KEWEI’s AI-driven injection system.

Related Keywords: KEWEI wax moulding machines, automated injection systems

3. Industry-Specific Applications

Aerospace: Thin-wall wax patterns for Inconel turbine blades (AMS 2175 compliant).

- Medical: Ultra-smooth models for titanium implants (Ra <0.8μm, ISO 13485).

- Automotive: High-volume moulds for aluminum EV components (IATF 16949).

Related Keywords: precision wax moulding, industrial casting solutions

4. Solving Investment Casting Injection Moulding Challenges

- Mould Wear? KEWEI’s diamond-coated moulds last 3X longer than standard tools.

- Cycle Time Bottlenecks? High-speed systems produce 500+ patterns/hour.

- Material Waste? Closed-loop recycling reclaims 95% of excess wax.

Related Keywords: injection moulding defects, casting process optimization

5. Partnering with KEWEI: Beyond Machines

Choosing KEWEI unlocks:

- Free Mould Design Review: Optimize CAD models for efficiency and cost savings.

- Global Compliance Support: CE, RoHS, and FDA certifications for seamless export.

- Lifetime Upgrades: Access AI software enhancements at no extra cost.

Request a Custom Quote Within 24 Hours!

Conclusion

KEWEI investment casting injection moulding technology bridges the gap between design and flawless production. With 20+ years of innovation, 50+ patents, and a client-first approach, KEWEI empowers manufacturers to dominate aerospace, medical, and automotive markets through precision, speed, and sustainability.

Ready to Transform Your Wax Patterns?

Contact KEWEI Today for Full Specifications!