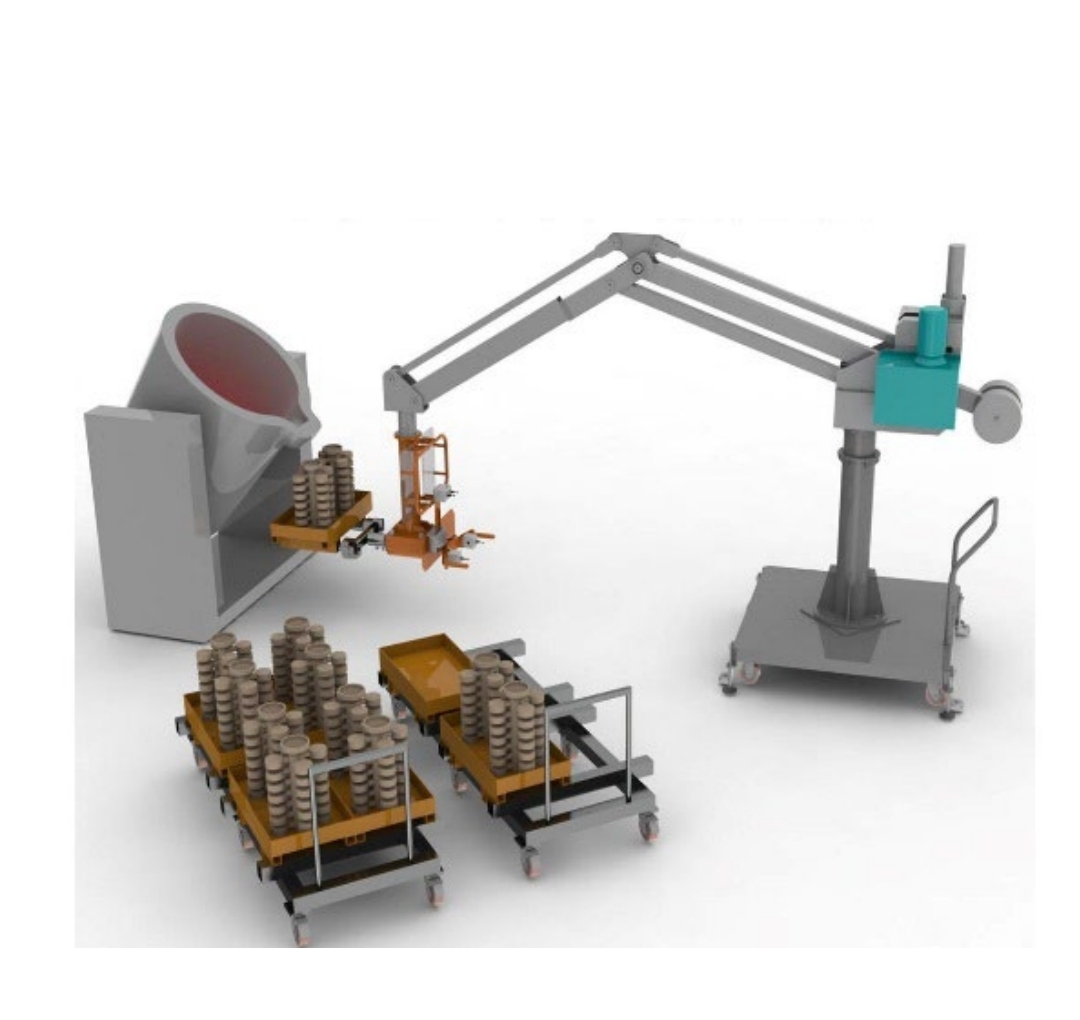

Investment Casting Flask

Engineered for Precision & Durability

In the investment casting process, the casting flask plays a pivotal role in ensuring dimensional accuracy and structural integrity. As a global leader in precision casting equipment, KEWEI (formerly KW Casting) designs investment casting flasks that redefine efficiency for aerospace, automotive, and energy industries. This blog explains why KEWEI’s flasks are trusted by manufacturers worldwide.

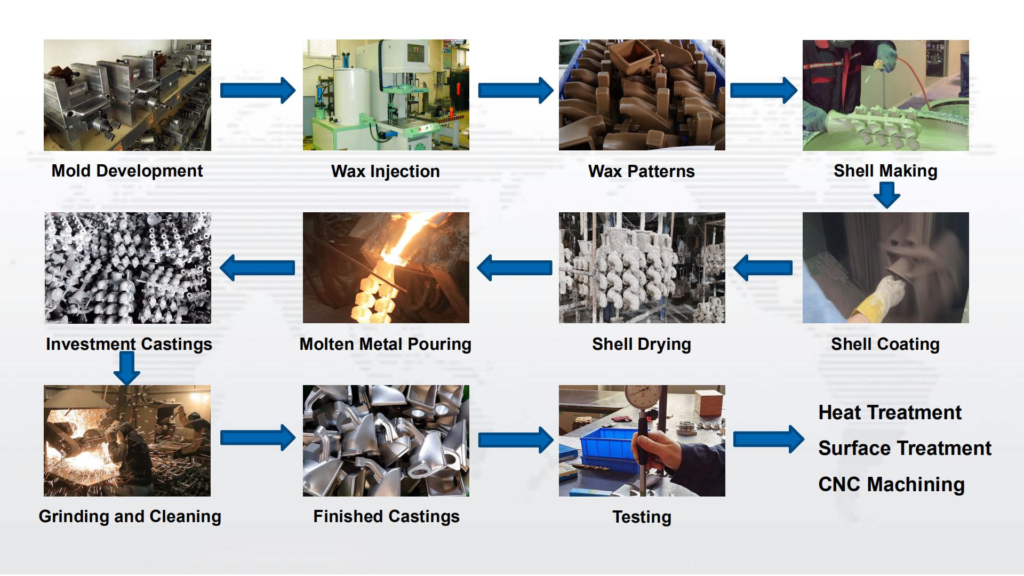

What is an Investment Casting Flask?

An investment casting flask is a specialized container that holds the ceramic shell mold assembly during the lost wax casting process. Unlike generic flasks, KEWEI’s designs integrate:

- High-Temperature Resistance: Withstands up to 1650°C for stainless steel and superalloy casting.

- Modular Configurations: Adjustable sizes (100mm to 800mm) for diverse part geometries.

- Reusable Durability: Made from aerospace-grade alloys, lasting 3X longer than standard flasks.

Related Keywords: lost wax casting flask, ceramic shell flask, precision casting equipment

Why Choose KEWEI Investment Casting Flasks?

KEWEI’s flasks solve critical industry pain points:

- Eliminate Warping: Proprietary rib-reinforced design prevents deformation under thermal stress.

- Accelerate Production: Quick-release clamps cut mold assembly time by 40%.

- Reduce Costs: Reusable flasks lower long-term expenses vs. disposable alternatives.

Case Study: A European automotive supplier reduced scrap rates by 18% after switching to KEWEI flasks.

Related Keywords: KEWEI casting flask, investment casting tooling

KEWEI’s Flask Design Innovations

Our engineering team prioritizes:

- AI-Optimized Airflow: Patented venting channels minimize gas porosity in final castings.

- Ergonomic Handling: Lightweight yet robust construction for safer operator use.

- Smart Tracking: RFID tags enable real-time flask lifecycle monitoring.

Related Keywords: ceramic shell molding equipment, investment casting automation

Applications Across Industries

KEWEI flasks are engineered for demanding scenarios:

- Aerospace: Cast turbine blades with zero tolerance for defects.

- Medical: Produce biocompatible implants with mirror-like finishes.

- Energy: Create corrosion-resistant valves for offshore drilling.

Related Keywords: industrial casting flasks, custom investment casting tools

How to Select the Right Flask Supplier

When partnering with KEWEI, you gain:

- Technical Consultations: Free process audits to optimize your workflow.

- Rapid Prototyping: Receive test flasks within 72 hours.

- Global Compliance: Flasks meet AS9100, ISO 13485, and API standards.

Related Keywords: investment casting flask supplier, lost wax casting solutions

A high-quality investment casting flask is the unsung hero of precision metal casting. KEWEI combines decades of expertise with cutting-edge engineering to deliver flasks that boost yield, speed, and ROI. Ready to Upgrade Your Foundry? Contact KEWEI for a free technical evaluation!