KEWEI Investment Casting Cutting Machine

Precision, Speed & Zero-Defect Finishing

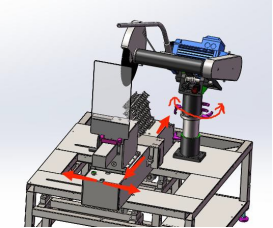

In the final stages of investment casting, precision cutting is critical to achieving flawless components ready for assembly. KEWEI, a global leader in intelligent foundry solutions, engineers investment casting cutting machine that redefine efficiency for aerospace, automotive, and medical industries. Combining AI-driven automation, ISO 9001-certified quality, and 20+ years of expertise, KEWEI’s machines deliver micron-level accuracy, reduce material waste by 30%, and accelerate production cycles.

1. Why Investment Casting Cutting Machine Matters?

Post-casting trimming impacts component integrity and profitability:

- Zero Damage: Maintain ±0.05mm tolerances for mission-critical parts like turbine blades and implants.

- Material Savings: Optimize cutting paths to reduce scrap rates by 25-40%.

- High Speed: Process 600+ parts/hour with KEWEI’s multi-axis robotic systems.

Related Keywords: casting trimming equipment, precision cut-off systems

2. KEWEI’s Cutting-Edge Technology

KEWEI’s investment casting cutting machines lead the industry through innovation:

- AI Vision Guidance: Real-time cameras detect gate locations and auto-adjust cutting paths.

- 5-Axis CNC Precision: Handle complex geometries (e.g., cooling channels in aerospace alloys).

- Eco-Design: 25% lower energy consumption vs. hydraulic competitors.

Case Study: An automotive client reduced post-processing costs by 35% using KEWEI’s laser-assisted cutting system for aluminum EV housings.

Related Keywords: KEWEI trimming machines, automated casting cut-off

3. Industry-Specific Solutions

- Aerospace: Vacuum-compatible machines for Inconel 718 components (AMS 2750 compliant).

- Medical: Cleanroom-grade systems for titanium implants (Ra <0.8μm surface finish).

- Automotive: High-speed abrasive cutters for high-volume aluminum parts (IATF 16949).

Related Keywords: industrial cutting equipment, precision investment casting tools

4. Solving Common Investment Casting Cutting Machine Challenges

- Burr Formation? KEWEI’s laser hybrid cutting eliminates secondary deburring.

- Tool Wear? Diamond-coated blades extend lifespan by 3X vs. standard tools.

- Slow Cycle Times? Dual-station processing cuts idle time by 50%.

Related Keywords: investment casting defects, trimming process optimization

5. Partnering with KEWEI: Beyond the Machine

Choosing KEWEI unlocks:

- Free Process Audit: Optimize your trimming workflow with expert recommendations.

- Smart Factory Integration: IoT connectivity for real-time production monitoring.

- Global Support: 24/7 remote diagnostics and spare parts hubs in 15 countries.

Related Keywords: investment casting machine supplier, smart foundry solutions

Conclusion

A KEWEI investment casting machine is the ultimate solution for achieving flawless, market-ready components. With AS9100 aerospace certification, AI-driven precision, and a client-first approach, KEWEI empowers manufacturers to slash costs, boost throughput, and dominate global markets.

Ready to Transform Your Finishing Process?

Contact KEWEI Today for a Free Machine Demonstration!