Investment Casting and Machining Equipment

KEWEI Precision Solutions

At KEWEI, we specialize in providing state-of-the-art investment casting and machining equipment designed to meet the highest standards of precision, efficiency, and reliability. Whether you’re producing aerospace components, medical implants, or automotive parts, our equipment ensures exceptional quality and performance.

Why Choose KEWEI’s Investment Casting and Machining Equipment?

- High Precision: Achieve tolerances as tight as ±0.05mm.

- Material Versatility: Compatible with stainless steel, aluminum, titanium, and superalloys.

- Energy Efficiency: Advanced technology reduces energy consumption by up to 30%.

- Durability: Built with industrial-grade components for long-lasting performance.

KEWEI’s Core Equipment for Investment Casting and Machining

- Wax Injection Machines

- Function: Produce precise wax patterns for casting.

- Key Features: Temperature control, multi-cavity molds, high-speed cycling.

- Why Choose KEWEI: Our wax injectors are designed for high precision and durability, ensuring flawless wax patterns every time.

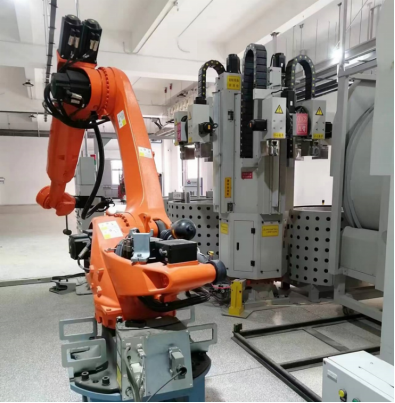

- Ceramic Shell Coating Systems

- Function: Apply ceramic layers to wax patterns.

- Key Features: Robotic arms, adjustable slurry viscosity, drying chambers.

- Why Choose KEWEI: KEWEI’s coating systems deliver uniform ceramic shells, reducing defects and improving casting quality.

- Vacuum Casting Units

- Function: Pour molten metal into ceramic molds under vacuum.

- Key Features: Porosity-free casting, precise temperature control.

- Why Choose KEWEI: Our vacuum casting units ensure defect-free castings, ideal for aerospace and medical applications.

- CNC Machining Centers

- Function: Precision machining of cast parts.

- Key Features: 5-axis capability, high-speed spindles, advanced control systems.

- Why Choose KEWEI: Our CNC machines deliver unmatched accuracy and surface finish, perfect for critical components.

Applications of KEWEI’s Equipment

- Aerospace: Turbine blades, engine components.

- Medical: Implants, surgical instruments.

- Automotive: Lightweight alloys for EVs.

- Energy: Wind turbine parts, pump housings.

Why Choose KEWEI: Our equipment is trusted by leading manufacturers worldwide for its precision and reliability.

Benefits of Choosing KEWEI’s Equipment

- End-to-End Solutions: From casting to machining, we provide complete equipment solutions.

- Advanced Technology: State-of-the-art machines designed for efficiency and precision.

- Quality Assurance: ISO-certified manufacturing processes and rigorous quality control.

- Global Support: Dedicated after-sales team for installation, training, and maintenance.

FAQs About Investment Casting and Machining Equipment

Q: What materials can be processed with KEWEI’s equipment?

A: Stainless steel, aluminum, titanium, superalloys, and more.

Q: How do I ensure part accuracy?

A: KEWEI’s advanced CNC machining ensures tolerances as tight as ±0.05mm.

Q: Can KEWEI’s equipment handle large-scale production?

A: Yes! We offer scalable solutions for both prototyping and mass production.

Ready to Elevate Your Production with KEWEI’s Equipment?

✅ Free Consultation: Get expert advice tailored to your needs.

✅ Competitive Quotes: Compare prices from top suppliers.

✅ Fast Delivery: Minimize downtime with quick shipping.