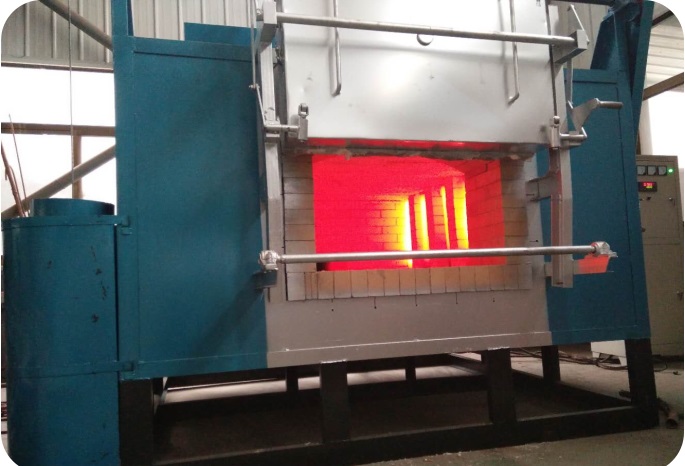

Foundry Shell Roaster for Investment Casting

Achieving Smooth, Flawless Finishes

Foundry Shell Roaster For investment casting,we have two power kinds-electric type or gas:

- Foundry Shell Roaster Structure:

The furnace adopts a box structure. The furnace body is composed of a high-temperature refractory brick layer, a light-weight thermal insulation brick layer, a high-temperature thermal insulation layer and a steel shell. The furnace has a good resistance to burning and heat preservation. Two-nozzle two-sided gas, high-speed vortex air pumping air,

waste heat recovery device to preheat the intake air, the flue is a non-inline structure, and the chain-type furnace door lifting mechanism is light and reliable.

- Control:

The control uses an internal feedback closed-loop system consisting of a fan, a temperature sensor, and a temperature controller. The combustion system is fully controlled in the range of 800 ~ 1200 ° C, automatically extinguishes and ignites, maintains a constant temperature, and saves gas.

- Burning:

When burning on both sides, a flame vortex is formed in the furnace during combustion, and the flue gas is discharged from the non-inline flue, so that the mold shell absorbs heat more fully, heats up quickly, the temperature is uniform, and the thermal efficiency is high. The combustion effect is better, more energy efficient, and the heating speed is faster.

- Uses:

This equipment is suitable for the baking of mold shells and heat treatment of steel parts in the investment casting industry.

- Mainfeatures:

Double nozzles and gas on both sides to form flame vortex;

Waste heat recovery device preheats intake air and improves combustion efficiency; High-speed vortex air pump for air supply and stable operation.

Foundry Shell Roaster Application: It is suitable for roasting of mold shells in precision casting

Foundry Shell Roaster Specification :

|

Description |

Unit | Quantity |

| Power | KW | 150 |

| Heating time of cold furnace | min | 90-120 |

| The highest temperature | ℃ | 1300 |

| Working temperature | ℃ | 0-1250 can adjust at will |

| Power supply | 380V 50Hz | |

| Heating components | Y/heat | |

| Temperature control precision | Plus or minus 1° | |

| Furnace temperature uniformity | Plus or minus 5° or less | |

| Chamber size | mm | 1500*1500*600 |

| Boundary size | mm | 2600*2500*2500 |

| Weight | kg | 6500 |

Why Choose Us?

- Expertise: Decades of experience in foundry equipment manufacturing.

- Quality Assurance: Rigorous testing to ensure top performance.

- Customer Support: Dedicated service team for installation, training, and maintenance.

- Customize: we can customize the capacity according to customer foundry plant need.

Upgrade your investment casting process today! Contact us now for a free consultation and discover how our Shell Knockout Machine can transform your production line.

We Also Offer Complete Production Lines in Turnkey Solutions

In addition to the Foundry Shell Roaster, we provide complete turnkey production lines tailored to your specific needs. Our comprehensive solutions ensure seamless integration and optimized production, from start to finish. Turn to Contact us page to talk more with detials.