Double Station Wax Injection Machine

for Investment Casting

Our Double Station Wax Injection Machine is a state-of-the-art solution designed to enhance productivity, precision, and efficiency in investment casting. Combining advanced automation with innovative temperature and pressure control systems, this machine ensures high-quality wax patterns while reducing production costs and labor requirements.

Double Station Wax Injection Machine Key Features

- Automated Wax Supply System:

- The machine operates in a wax cylinder-less mode, supporting both automatic and manual wax supply.

- Eliminates the need for bulky traditional wax cylinders, simplifying operations and saving space.

- Improved Productivity:

- Directly integrates the wax precipitation net into the wax injection process, bypassing the traditional 24-hour wax bath resting period.

- Shortens the production cycle, reduces equipment costs, and minimizes labor expenses.

- Precision Mold Temperature Control:

- Equipped with cooling water channels in the upper and lower molds to maintain optimal mold temperature.

- Ensures consistent wax part quality by preventing mold temperature fluctuations.

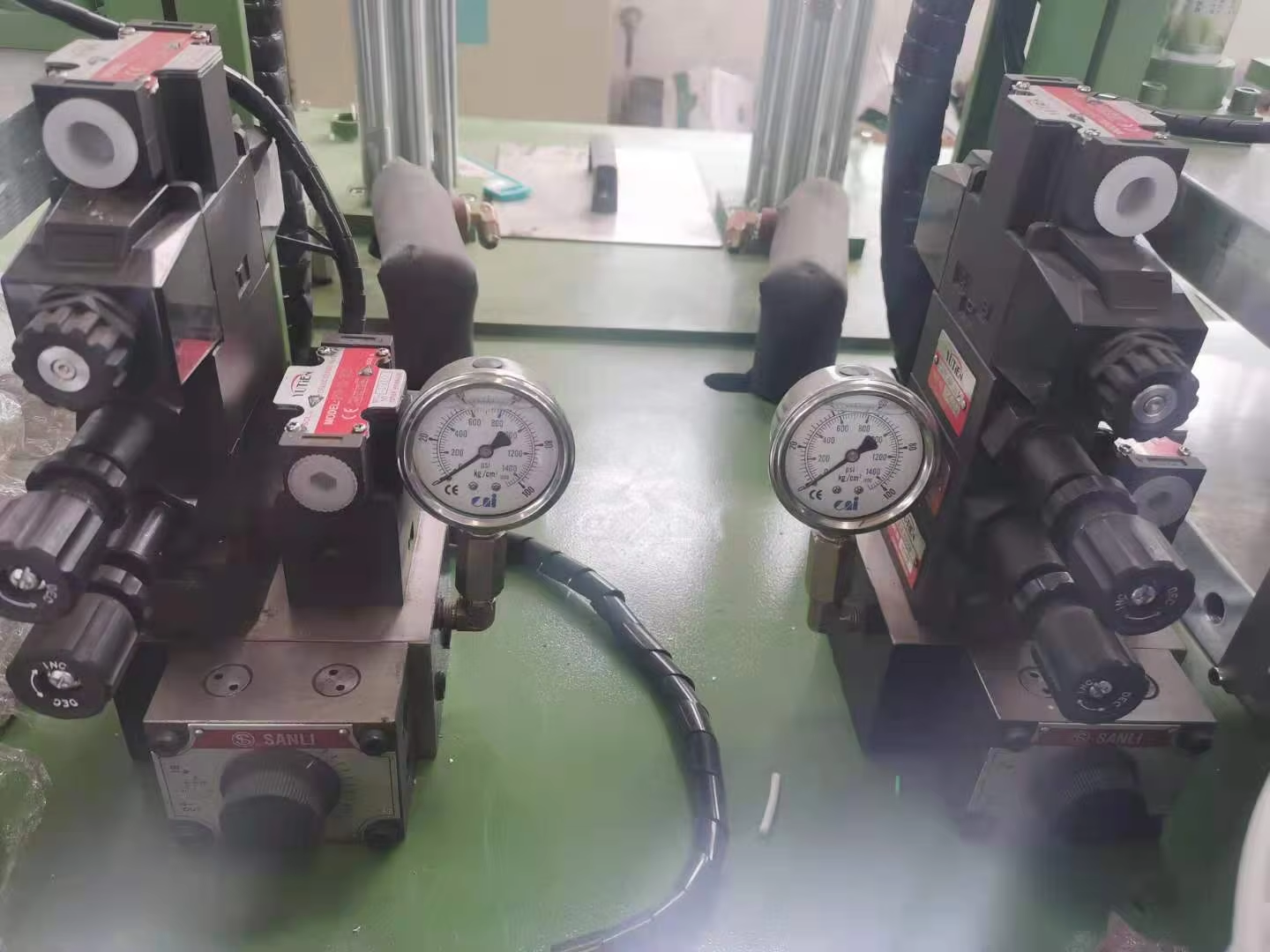

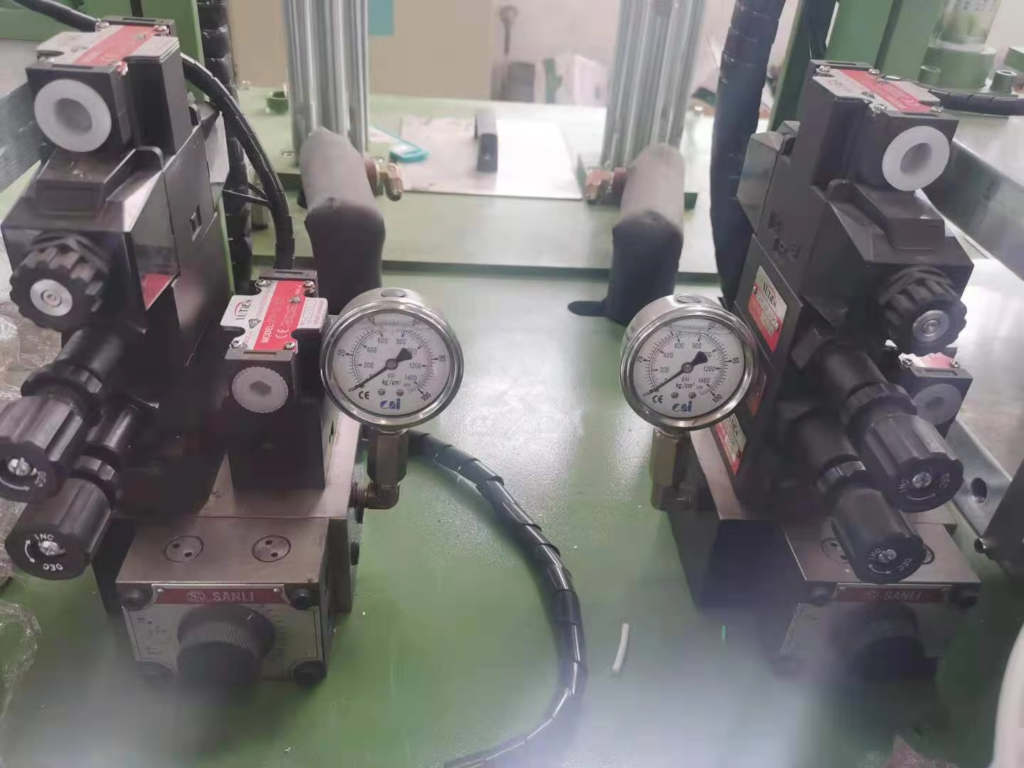

- Pressure Stabilization System:

- Features a constant-pressure clamping system for stable wax part weight and improved quality.

- Advanced Temperature Control Technology:

- Utilizes a triple-tube wax cooler with heating medium oil for precise temperature regulation.

- Dual digital temperature control ensures rapid cooling or heating (85°C to 55°C) with an error margin of ≤0.2°C.

- Efficient Oil Pressure System:

- Incorporates a larger cooling suppressor for stable oil temperature and low failure rates.

- Compact design ensures easy maintenance and high reliability.

- High Automation & User-Friendly Operation:

- Offers a high degree of automation, enabling efficient production with minimal manual intervention.

- Supports wax injection via telescopic nozzle or movable worktable for added flexibility.

- Exceptional Mold Precision:

- Delivers wax molds with dimensional tolerances ≤0.015mm and surface roughness between Ra3.2 and Ra6.3.

- Ensures high precision and stability for superior casting quality.

- Market-Leading Performance:

- Combines reliable performance, high productivity, and advanced automation to replace manual operations entirely.

- A leading solution in the Chinese market, trusted for its efficiency and precision.

Benefits

- Cost Savings: Reduces production time, labor costs, and equipment expenses.

- Enhanced Quality: Ensures consistent wax part dimensions and surface finish.

- Increased Efficiency: High automation and advanced features streamline operations.

- Durability: Robust construction and low failure rates ensure long-term reliability.

Why Choose Our Double Station Wax Injection Machine?

- Innovative Design: Combines advanced technology with practical features for superior performance.

- Reliability: Built with durable materials and precision engineering for long-term use.

- Operator-Friendly: Focused on safety, ease of use, and maintenance efficiency.

Upgrade your wax pattern production with our Double Station Wax Injection Machine! Contact us today to learn more or request a quote.

We Also Offer Complete Production Lines in Turnkey Solutions

In addition to the Wax Injection Machine, we provide complete turnkey production lines tailored to your specific needs. Our comprehensive solutions ensure seamless integration and optimized production, from start to finish. Turn to Contact us page to talk more with detials.