Coating Machine for Investment Casting

KEWEI’s Ceramic Shell Solutions

In investment casting, the coating machine is where wax patterns transform into durable ceramic shells. As a leading investment casting coating machine manufacturer, KEWEI engineers systems that ensure uniform slurry application, minimal defects, and maximum efficiency—critical for aerospace, medical, and automotive industries.

Why Coating Machines Define Casting Quality

- Uniform Shell Thickness: Prevent cracks and inclusions during metal pouring.

- Material Efficiency: Optimize slurry usage with robotic precision.

- Speed: Automate dipping cycles to reduce production time.

- Versatility: Compatible with silica, zircon, and alumina slurries.

Why KEWEI? Our ceramic coating machines are trusted by high-quality investment casting factories globally for repeatable, defect-free results.

KEWEI’s Core Coating Machines for Investment Casting

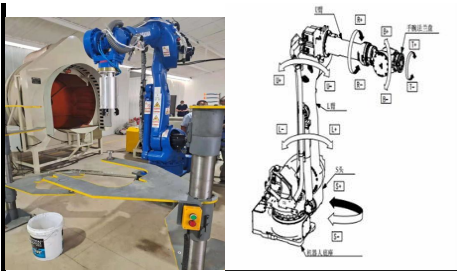

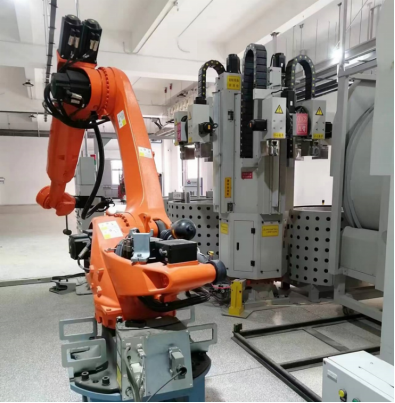

- Automated Dip Coating Robots

- Function: Apply ceramic slurry layers with ±0.1mm uniformity.

- KEWEI Edge: AI adjusts viscosity and drying time for each layer.

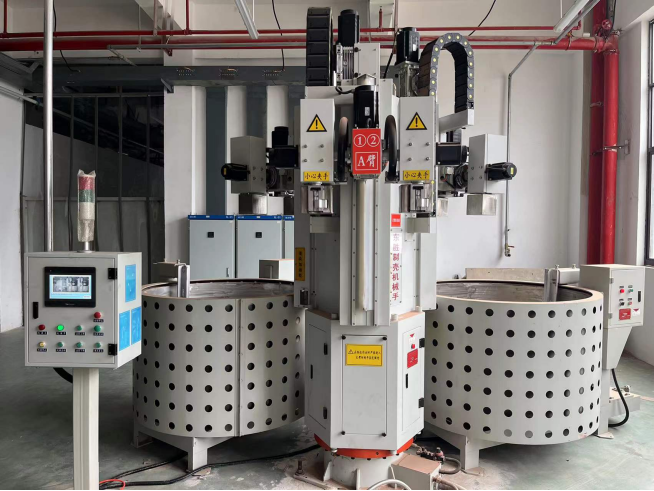

- Rotary Coating Systems

- Function: High-speed coating for small to medium parts (e.g., dental implants).

- KEWEI Edge: 360° coverage with minimal manual intervention.

- Large-Scale Coating Tanks

- Function: Dip oversized wax assemblies (e.g., turbine blades).

- KEWEI Edge: Temperature-controlled slurry for consistent curing.

- Dust-Free Drying Chambers

- Function: Harden ceramic shells without contamination.

- KEWEI Edge: Humidity and airflow optimized for fast cycles.

Applications of KEWEI’s Coating Machines

- Aerospace: Uniform ceramic shells for turbine blades (e.g., Rolls-Royce suppliers).

- Medical: Biocompatible coatings for titanium implants.

- Automotive: High-volume coating for EV motor housings.

- Energy: Thick-shell molds for high-temperature alloy valves.

Case Study: A top investment casting supplier reduced shell rejection rates by 60% using KEWEI’s robotic dip coating systems.

How to Choose a Coating Machine for Investment Casting

- Production Scale: Match machine capacity (prototype vs. mass production).

- Slurry Type: Ensure compatibility with zircon, fused silica, etc.

- Automation Level: Opt for robotic systems for complex geometries.

- Sustainability: Slurry recycling and energy-efficient drying.

Why KEWEI? We offer coating machines for investment casting tailored to your exact needs, from R&D labs to full-scale foundries.

FAQs About Coating Machines in Investment Casting

Q: How many coating layers are needed for a ceramic shell?

A: Typically 6–9 layers, depending on part size and material. KEWEI’s machines automate layer counting and quality checks.

Q: Can KEWEI’s machines handle hybrid slurry blends?

A: Yes! Our systems support custom slurry formulations for unique applications.

Q: What maintenance do coating machines require?

A: Daily slurry filtration, nozzle cleaning, and quarterly calibration. KEWEI provides predictive maintenance tools.

Ready to Elevate Your Shell Coating Process?

✅ Free Trial: Test KEWEI’s coating machine with your slurry.

✅ Expert Support: 24/7 technical assistance and training.

✅ Global Delivery: Installed in 30+ countries.

Ready to upgrade your foundry? Explore our curated selection of advanced metal casting solutions and request a personalized consultation today!