Casting Invest Molds

Precision Engineering for Complex Metal Components

Introduction

In the world of precision manufacturing, casting invest molds (also known as investment casting molds) are the cornerstone of creating intricate, high-performance metal parts. KEWEI, a global leader in advanced foundry solutions, engineers casting invest molds that combine cutting-edge materials, AI-driven design, and decades of expertise. Trusted by aerospace, automotive, and medical industries, KEWEI’s molds deliver unmatched accuracy and durability. Discover why OEMs worldwide rely on our technology.

1. What Are Casting Investment Molds?

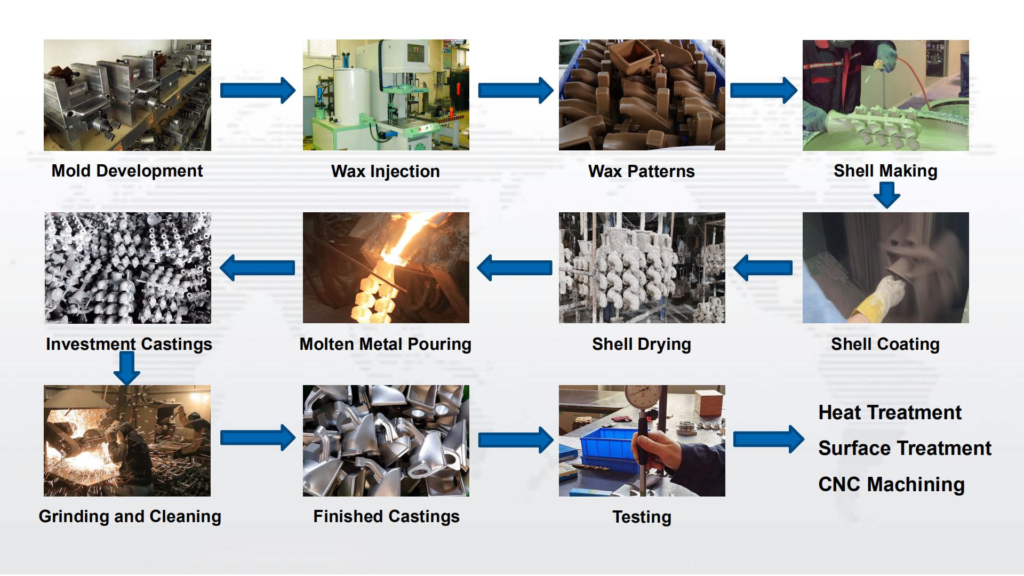

Casting invest molds are specialized tools used in the investment casting process to shape molten metal into complex geometries. KEWEI’s molds excel through:

- Ceramic Shell Technology: High-purity silica and zirconia blends withstand temperatures up to 1700°C.

- Precision Wax Patterns: CNC-machined or 3D-printed for micron-level accuracy.

- Modular Design: Reusable molds reduce long-term costs for high-volume production.

Related Keywords: investment casting molds, ceramic shell molds, precision casting tooling

2. KEWEI’s Casting Invest Molds: Why They Lead

KEWEI’s casting invest molds solve critical industry challenges with:

- Zero Defect Guarantee: AI-optimized gating systems eliminate porosity and cold shuts.

- Rapid Turnaround: Prototype molds delivered in 7 days via additive manufacturing.

- Material Versatility: Compatible with aluminum, titanium, superalloys, and more.

Case Study: A European automotive supplier reduced post-processing costs by 35% using KEWEI’s reusable invest molds for EV battery housings.

Related Keywords: KEWEI ceramic molds, custom investment casting tooling

3. Industry-Specific casting invest molds Solutions

KEWEI tailors molds to demanding applications:

- Aerospace: Thin-wall molds for turbine blades with ±0.05mm tolerances.

- Medical: FDA-compliant molds for biocompatible titanium implants.

- Energy: Corrosion-resistant molds for offshore valve components.

Related Keywords: high-temperature casting molds, industrial investment casting

4. Overcoming Common Mold Challenges

- Mold Cracking? KEWEI’s graded ceramic layers prevent thermal stress fractures.

- Dimensional Errors? Real-time simulation predicts shrinkage and warpage.

- High Costs? Modular designs slash tooling expenses by 50% over 5 years.

Related Keywords: ceramic mold defects, investment casting optimization

5. Partnering with KEWEI: Beyond Mold Supply

Choosing KEWEI unlocks end-to-end support:

- Free Design Review: Our engineers optimize your CAD models for mold efficiency.

- Global Certification: Molds comply with AS9100 (aerospace) and ISO 13485 (medical).

- Lifetime Maintenance: On-site technicians and spare parts logistics.

Related Keywords: casting invest mold supplier, precision foundry solutions

Conclusion

In an era where precision and efficiency define competitiveness, KEWEI casting invest molds set the gold standard. Backed by 15+ years of R&D, smart manufacturing, and a client-centric approach, we empower foundries to achieve zero-defect production and dominate global markets. Ready to Revolutionize Your Casting Process? Contact KEWEI Today for a Free Mold Design Audit!