Automatic Shell Making System

for Investment Casting

Transform your investment casting process with our state-of-the-art Automatic Shell Making System.

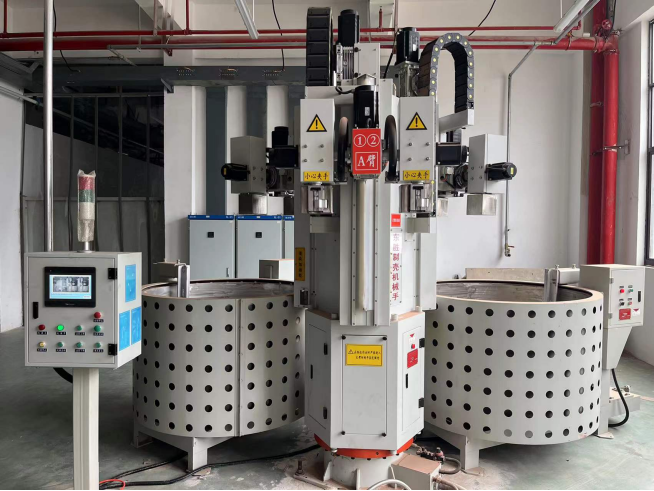

1) Mechanical part: The rotary base is equipped with four arms, the rotary base can be rotated successively, and each arm has the function of lifting, swinging and rotating. Thus it can realize the action of picking, hanging, dipping, dripping and sanding of the mold shell.

2) Electrical part: Through the programmable logic controller (PLC) and touch screen control drive, the stepping system drives the rotation of the turntable, the lifting and lowering of each arm, the swinging of each arm, and the rotation of each mold shell. The dipping and sanding actions are carried out automatically respectively.

Designed for precision, efficiency, and reliability, this system automates the entire shell-making process, from slurry dipping to sand coating, ensuring consistent quality and reducing labor costs. Ideal for high-volume production, our system is built to meet the demands of modern foundries.

- Fully Automated Operation:

- Automates slurry dipping, sand coating, and drying, reducing manual labor and human error.

- High Precision:

- Ensures uniform shell thickness and consistent quality for every casting.

- Robust Construction:

- Built with durable materials to withstand harsh foundry environments.

- User-Friendly Interface:

- Equipped with an intuitive HMI for easy operation and monitoring.

- Energy Efficient:

- Optimized design reduces energy consumption, lowering operational costs

automatic shell making system Specification sheet:

Number of stations X Number of shells: 3X2(4X2)pcs

Max workpiece measure: ¢450X500

Max workpiece: 30Kg

Working speed: ≥3(4) group/min

Using electric: 380V 50Hz (Three-phase five-wire system)

Installed power: 9(11)KW(The power is much less than this

value during normal operation)

Min. hanging shell gyration radius: R1010

Max. hanging shell gyration radius: R1660

Dimensions: approximately ¢1800X3000

Weight: approximately 2.8(3.2)T

Benefits

- Improved Productivity: Faster shell production means shorter cycle times and higher output.

- Cost Savings: Reduces labor costs and minimizes material waste.

- Enhanced Quality: Ensures consistent shell quality for high-precision castings.

- Durability: Engineered for long-term reliability in demanding environments.

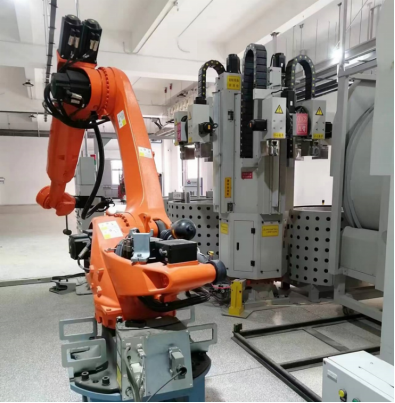

We Also Offer Complete Production Lines in Turnkey Solutions

In addition to the automatic shell making system, we provide complete turnkey production lines tailored to your specific needs. Our comprehensive solutions ensure seamless integration and optimized production, from start to finish. Turn to Contact us page to talk more with detials.