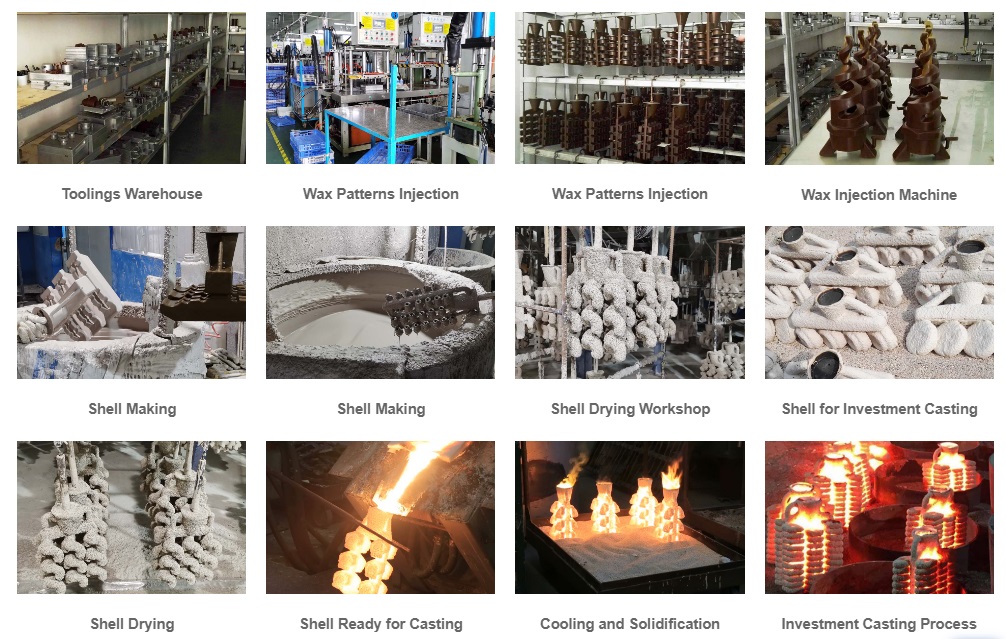

Investment casting lost Wax equipment

In a world where a single micron can define success, investment casting lost wax equipment isn’t just machinery—it’s the bridge between raw material and engineering marvel. At KEWEI, we’ve reimagined this bridge. Here’s how our equipment turns wax into wings, gears, and life-saving implants.

The Hidden Challenges of Lost Wax Casting (And How KEWEI Solves Them)

Problem 1: “My wax patterns warp under heat.”

- KEWEI’s Fix: Patented temperature control (±0.5°C) ensures wax flows uniformly, even for ultra-thin walls (0.3mm).

Problem 2: “Ceramic shells crack during dewaxing.”

- KEWEI’s Fix: AI-driven ceramic slurry formulations adapt to humidity and material batches.

Problem 3: “Porosity ruins my aerospace parts.”

- KEWEI’s Fix: Vacuum-assisted casting chambers with 99.9% air removal.

KEWEI’s Lost Wax Equipment: Where Innovation Meets Industry

Case Study: Turbine Blades for Jet Engines

- Challenge: Produce 100 blades/day with zero porosity and ±0.05mm tolerance.

- KEWEI Solution:

- Smart Wax Injector: 8-cavity molds with real-time pressure monitoring.

- Self-Learning Coating Robot: Adjusts slurry viscosity based on shell thickness.

- Result: 40% faster cycle time, 99.8% defect-free yield.

Why This Matters: For industries where failure isn’t an option, precision isn’t a luxury—it’s survival.

Beyond Machines: The KEWEI Ecosystem

- AI-Powered Predictive Maintenance

- Sensors predict wear in wax nozzles or ceramic pumps before they fail.

- Material Science Lab

- Co-develop custom wax-resin blends for your unique needs.

- Zero-Waste Training

- Virtual reality (VR) simulations train operators without wasting materials.

The Future of Lost Wax Casting (Spoiler: It’s Green)

- Energy Recovery: 80% of furnace heat recycled to preheat wax molds.

- Bio-Waxes: Partnering with startups to replace petroleum-based waxes.

- Circular Ceramics: Crushed shells reused in 3D-printed molds.

KEWEI’s Promise: By 2025, our equipment will cut carbon footprints by 30%.

“But Does It Work for My Small Foundry?”

- Startup-Friendly Leasing: Pay-per-use models for wax injectors.

- Modular Design: Scale from 10 to 10,000 parts/month without overhaul.

- Community Hub: Join KEWEI’s user forum to share tips with global peers.

Ready to Write Your Precision Casting Story?

✅ Book a Live Demo: Watch a KEWEI machine craft your sample part.

✅ Download the “Lost Wax Playbook”: Free guide to reducing defects by 50%.

✅ Join the Green Revolution: Ask about our eco-upgrade incentives.

Ready to upgrade your foundry? Explore our curated selection of advanced metal casting solutions and request a personalized consultation today!