Industrial Lost Wax Casting Equipments | KEWEI Precision Solutions

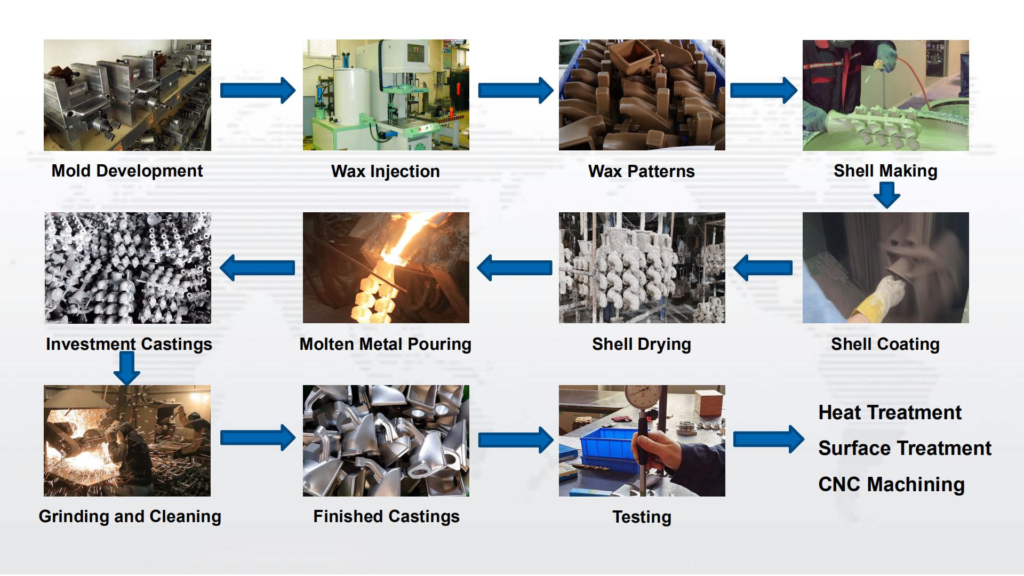

Industrial lost wax casting equipments are essential for producing high-quality, complex metal parts with exceptional precision and surface finish. At KEWEI, we specialize in providing state-of-the-art equipment designed to meet the demands of modern foundries across industries.

Why Choose KEWEI’s Industrial Lost Wax Casting Equipment?

- High Precision: Achieve tolerances as tight as ±0.1mm.

- Material Versatility: Compatible with stainless steel, aluminum, titanium, and superalloys.

- Energy Efficiency: Advanced technology reduces energy consumption by up to 30%.

- Durability: Built with industrial-grade components for long-lasting performance.

Key Equipment for Industrial Lost Wax Casting

- Wax Injection Machines

- Function: Produce precise wax patterns for casting.

- Key Features: Temperature control, multi-cavity molds, high-speed cycling.

- Why Choose KEWEI: Our wax injectors are designed for high precision and durability, ensuring flawless wax patterns every time.

- Ceramic Shell Coating Systems

- Function: Apply ceramic layers to wax patterns.

- Key Features: Robotic arms, adjustable slurry viscosity, drying chambers.

- Why Choose KEWEI: KEWEI’s coating systems deliver uniform ceramic shells, reducing defects and improving casting quality.

- Vacuum Investing & Casting Machines

- Function: Remove air bubbles and pour molten metal under vacuum.

- Key Features: Vacuum levels ≤50mbar, precise temperature control.

- Why Choose KEWEI: Our vacuum casting units ensure porosity-free castings, ideal for aerospace and medical applications.

- Dewaxing & Sintering Furnaces

- Function: Remove wax and harden ceramic shells.

- Key Features: High-temperature capability, energy efficiency.

- Why Choose KEWEI: Our furnaces are engineered for optimal energy use and consistent performance.

Applications of Industrial Lost Wax Casting Equipment

- Aerospace: Turbine blades, engine components.

- Medical: Implants, surgical instruments.

- Automotive: Lightweight alloys for EVs.

- Energy: Wind turbine parts, pump housings.

Why Choose KEWEI: Our equipment is trusted by leading manufacturers worldwide for its precision and reliability.

Benefits of Choosing KEWEI’s Equipment

- End-to-End Solutions: From wax injection to final casting, we provide complete equipment solutions.

- Advanced Technology: State-of-the-art machines designed for efficiency and precision.

- Quality Assurance: ISO-certified manufacturing processes and rigorous quality control.

- Global Support: Dedicated after-sales team for installation, training, and maintenance.

FAQs About Industrial Lost Wax Casting Equipment

Q: What materials can be processed with KEWEI’s equipment?

A: Stainless steel, aluminum, titanium, superalloys, and more.

Q: How do I ensure part accuracy?

A: KEWEI’s advanced equipment ensures tolerances as tight as ±0.1mm.

Q: Can KEWEI’s equipment handle large-scale production?

A: Yes! We offer scalable solutions for both prototyping and mass production.

Ready to Elevate Your Production with KEWEI’s Equipment?

✅ Free Consultation: Get expert advice tailored to your needs.

✅ Competitive Quotes: Compare prices from top suppliers.

✅ Fast Delivery: Minimize downtime with quick shipping.