Lost Wax Investment Casting Equipments

The Key to Complex, High-Quality Components

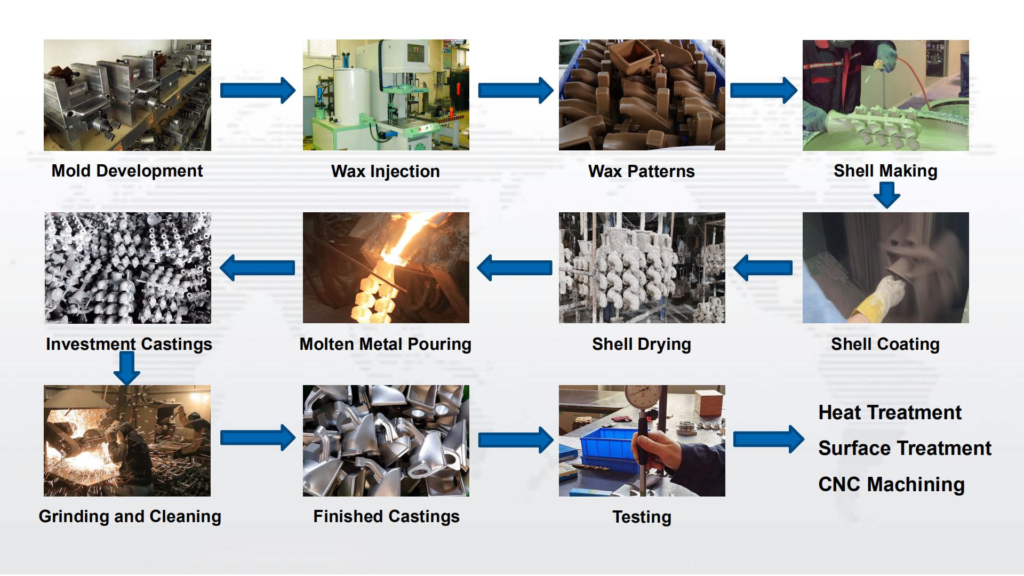

The lost wax investment casting process relies on precision equipment to transform wax patterns into flawless metal parts. At KEWEI, we provide end-to-end lost wax investment casting equipments—from wax injection to final finishing—trusted by aerospace, medical, and automotive industries for its accuracy, efficiency, and reliability.

Essential Lost Wax Investment Casting Equipment

- Wax Injection Machines

- Function: Produce detailed wax patterns with tolerances as tight as ±0.05mm.

- KEWEI Edge: Multi-cavity molds and AI-driven temperature control.

lose wax injection machine

- Ceramic Shell Coating Systems

- Function: Apply uniform ceramic layers to create durable molds.

- KEWEI Edge: Robotic dipping and real-time viscosity monitoring.

Ceramic Shell Coating Systems

- Vacuum Casting Furnaces

- Function: Pour molten metal under vacuum (≤50mbar) to eliminate porosity.

- KEWEI Edge: Ideal for reactive metals like titanium and zirconium.

Metal Melting Machine in Investment Casting

- Dewaxing Autoclaves

- Function: Remove wax from ceramic shells without residue.

- KEWEI Edge: Energy-efficient steam cycles and rapid cooling.

loast wax casting dewaxing kettle

- CNC Finishing Machines

- Function: Achieve final dimensions and surface finishes (Ra ≤0.4μm).

- KEWEI Edge: 5-axis precision for complex geometries.

lost foam casting cnc machines

Why Choose KEWEI’s Lost Wax Investment Casting Equipment?

- Integrated Solutions: Seamless workflow from wax to finished casting.

- Material Versatility: Compatible with stainless steel, aluminum, superalloys, and more.

- Energy Efficiency: Reduce costs by 30% with smart power management.

- Global Certifications: ISO 9001, AS9100, and CE compliance.

Case Study: A leading aerospace supplier reduced defects by 60% using KEWEI’s vacuum furnaces and ceramic coating systems.

Applications of KEWEI’s Equipments

- Aerospace: Turbine blades, fuel nozzles, and structural components.

- Medical: Biocompatible implants and surgical instruments.

- Automotive: Lightweight aluminum parts for electric vehicles.

- Energy: Corrosion-resistant valves and pump housings.

How to Select Lost Wax Investment Casting Machines

- Production Volume: Choose manual systems for prototyping or automated lines for mass production.

- Material Requirements: Match equipment to alloys (e.g., vacuum furnaces for titanium).

- Budget: Compare new vs. refurbished machines for cost optimization.

- After-Sales Support: Ensure suppliers offer training, maintenance, and spare parts.

Why KEWEI? We provide turnkey solutions with installation, training, and 24/7 global support.

FAQs About Lost Wax Investment Casting

Q: What’s the typical lead time for equipment delivery?

A: Standard machines ship in 4–6 weeks; custom systems may take 8–12 weeks.

Q: Can KEWEI’s equipment handle large-scale production?

A: Yes! Our automated lines support 10,000+ parts/month with IoT-driven efficiency.

Q: Do you offer financing options?

A: Yes—flexible leasing and payment plans are available for SMEs and large foundries.

Transform Your Casting Process with KEWEI!

✅ Free Consultation: Get expert advice on equipment selection.

✅ Competitive Quotes: Compare prices for new and refurbished machines.

✅ Fast Delivery: Installed and operational in 4–8 weeks.

Ready to upgrade your foundry? Explore our curated selection of advanced metal casting solutions and request a personalized consultation today!