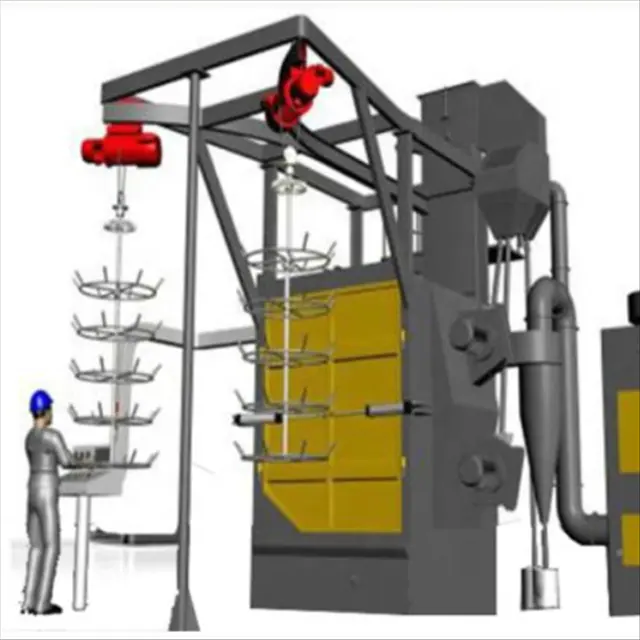

Investment Casting Conveyors

KEWEI’s Automated Solutions for Efficient Production

In the high-precision world of investment casting, Investment Casting Conveyors are the backbone of seamless production. KEWEI’s automated conveyors ensure smooth material flow—from wax pattern assembly to finished castings—minimizing downtime and maximizing efficiency for aerospace, automotive, and medical industries.

Why KEWEI’s Investment Casting Conveyors Stand Out

- Customized Design: Tailored layouts for your production line (linear, rotary, or overhead).

- High Load Capacity: Handle up to 2,000kg for large ceramic molds and castings.

- Heat Resistance: Withstand temperatures up to 300°C in sintering and cooling zones.

- Smart Automation: IoT-enabled tracking for real-time process monitoring.

Why KEWEI? Our conveyors integrate with wax injection machines and vacuum furnaces, creating a fully automated foundry ecosystem.

Key Types of Investment Casting Conveyors by KEWEI

- Belt Conveyors

- Function: Transport wax patterns and ceramic shells between stations.

- KEWEI Edge: Food-grade belts for medical and aerospace cleanliness standards.

- Roller Conveyors

- Function: Move heavy molds and castings through dewaxing and sintering.

- KEWEI Edge: Stainless steel rollers with anti-corrosion coating.

- Overhead Chain Conveyors

- Function: Suspend and transport parts through coating and drying cycles.

- KEWEI Edge: Programmable speed control for precise timing.

- Robotic Transfer Units

- Function: Automate part handling between casting and machining stations.

- KEWEI Edge: Collaborative robots (cobots) for flexible production.

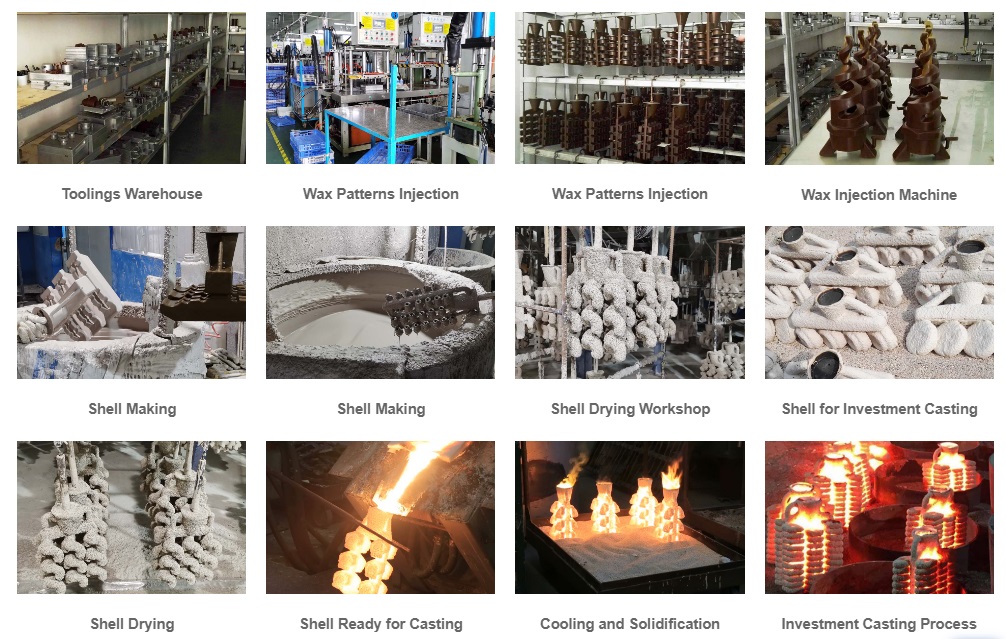

Applications of KEWEI’s Conveyors in Investment Casting

- Wax Assembly Line: Transport wax trees to coating stations.

- Ceramic Shell Drying: Uniformly rotate molds for even slurry drying.

- Post-Casting Handling: Transfer hot castings to cooling and finishing areas.

- Quality Inspection: Integrate with AI vision systems for defect detection.

Case Study: A leading automotive foundry increased throughput by 35% using KEWEI’s robotic conveyors for EV motor housings.

How to Choose the Right Investment Casting Conveyor

- Production Layout: Match conveyor type (belt, roller, overhead) to your floor plan.

- Environmental Needs: Heat resistance, corrosion protection, and cleanliness.

- Automation Level: Opt for IoT-enabled systems with ERP/MES integration.

- Scalability: Ensure modular designs for future expansion.

Why KEWEI? We provide turnkey conveyor solutions with installation, training, and 24/7 global support.

FAQs About Investment Casting Conveyors

Q: Can conveyors handle fragile ceramic shells?

A: Yes! KEWEI’s belt conveyors use vibration-dampening technology to prevent damage.

Q: How do I maintain a high-temperature conveyor?

A: Monthly lubrication and thermal sensor checks—KEWEI offers predictive maintenance plans.

Q: Are KEWEI’s conveyors compatible with legacy equipment?

A: Absolutely! Our systems integrate with existing wax injection machines and CNC grinders.

Upgrade Your Foundry with KEWEI’s Smart Conveyors!

✅ Free Layout Design: Optimize your production line efficiency.

✅ Custom Quote: Get pricing tailored to your throughput needs.

✅ Fast Delivery: Installed and operational in 4–8 weeks.

Ready to upgrade your foundry? Explore our curated selection of advanced metal casting solutions and request a personalized consultation today!