Wax Injection Machine

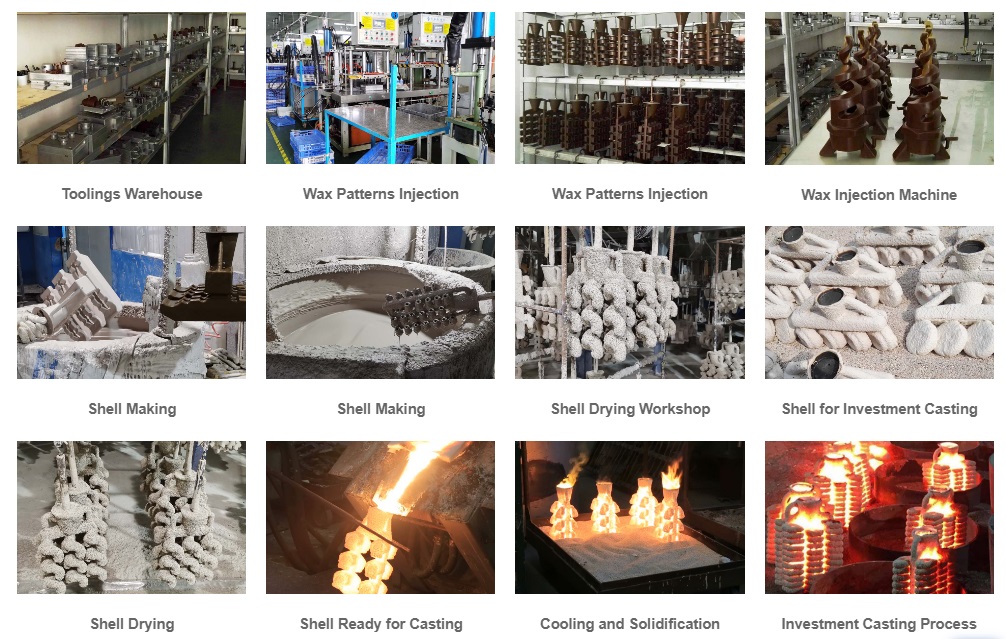

The Foundation of Flawless Investment Casting

The wax injection machine is the first critical step in investment casting, shaping intricate wax patterns that define the quality of final metal components. At KEWEI, we engineer high-precision wax injectors trusted by aerospace, medical, and automotive industries to achieve tolerances as tight as ±0.03mm.

Why KEWEI’s Wax Injection Machines Lead the Industry

- Micron-Level Precision: AI-driven temperature control (±0.5°C) ensures consistent wax flow.

- Multi-Cavity Molds: Produce 4–12 wax patterns per cycle for high-volume efficiency.

- Material Versatility: Compatible with synthetic, water-soluble, and bio-degradable waxes.

- Energy Efficiency: Servo-driven systems reduce power consumption by 30%.

Why KEWEI? Our machines are ISO 9001-certified and backed by a 10-year durability guarantee.

Key Features of KEWEI’s Wax Injection Machines

- Automated Ejection: Sensors detect and adjust release angles to prevent pattern damage.

- IoT Connectivity: Real-time monitoring of pressure, temperature, and cycle times.

- Quick-Change Molds: Reduce downtime with modular mold clamping systems.

-

Temperature Control: Dual-zone heating for molds and wax reservoirs.

Applications Across Industries

- Aerospace: Turbine blade wax patterns with ultra-thin walls (0.3mm).

- Medical: Biocompatible wax molds for titanium implants.

- Automotive: High-volume production of EV motor housings.

- Jewelry: Intricate designs with micro-details.

Case Study: A top investment casting supplier reduced wax scrap rates by 55% using KEWEI’s AI-driven injectors.

How to Choose the Right Wax Injection Machine

- Production Scale: Match machine capacity (prototype vs. 10,000+ parts/month).

- Mold Compatibility: Ensure compatibility with multi-cavity or single-cavity designs.

- Automation Level: Opt for robotic integration for lights-out production.

- Support Services: Prioritize suppliers offering training and spare parts (e.g., KEWEI’s 24/7 global support).

FAQs About Wax Injection Machines

Q: What’s the difference between hydraulic and electric wax injectors?

A: Hydraulic offers higher pressure (up to 150 bar) for complex molds; electric is quieter and more energy-efficient.

Q: Can KEWEI’s machines handle hybrid wax-resin blends?

A: Yes! Our systems support custom material formulations.

Q: How long does mold setup take?

A: KEWEI’s quick-change systems reduce setup to <15 minutes.

Ready to Revolutionize Your Wax Pattern Production?

✅ Free Trial: Test KEWEI’s wax injection machine with your molds.

✅ Custom Quote: Get pricing tailored to your production needs.

✅ Fast Delivery: Installed in 4–6 weeks with training included.

Ready to upgrade your foundry? Explore our curated selection of advanced metal casting solutions and request a personalized consultation today!