Metal Heating Machine in Investment Casting

The Heart of Precision Melting

In investment casting, the Metal Heating Machine in Investment Casting is where raw materials transform into molten perfection. At KEWEI, we design advanced heating systems—like vacuum induction furnaces and resistance melters—that ensure precise temperature control, minimal oxidation, and flawless castings for aerospace, medical, and automotive industries.

Why Metal Heating Machines Are Critical

- Material Integrity: Prevent oxidation and impurities in molten metal.

- Energy Efficiency: Reduce power consumption with smart heating cycles.

- Precision Control: Maintain ±5°C accuracy for alloys like titanium and Inconel®.

- Scalability: From small batches to high-volume production.

Why KEWEI? Our metal heating machines are trusted by top investment casting manufacturers for their reliability and performance.

Key Metal Heating Machines for Investment Casting

- Vacuum Induction Melting (VIM) Furnaces

- Function: Melt alloys under vacuum for zero oxidation.

- KEWEI Edge: Oxygen levels <10ppm for aerospace-grade materials.

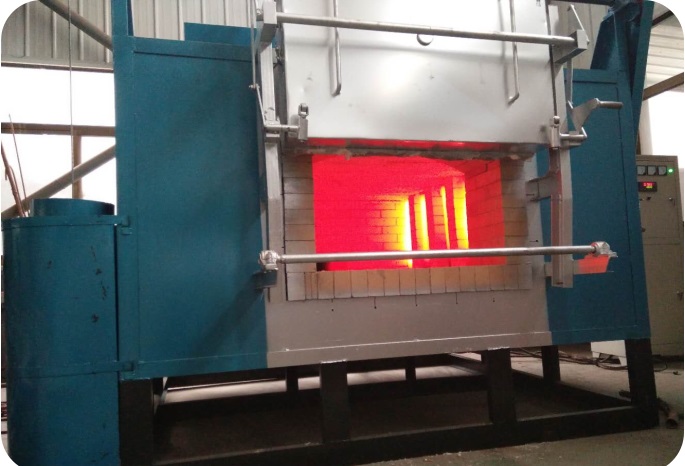

- Resistance Heating Furnaces

- Function: Heat ceramic molds and metal charges uniformly.

- KEWEI Edge: Multi-zone temperature control for large molds.

- Induction Melting Systems

- Function: Rapidly melt metals with minimal energy loss.

- KEWEI Edge: Frequency tuning for stainless steel, aluminum, and copper.

- Gas-Fired Crucible Furnaces

- Function: Cost-effective melting for non-reactive alloys.

- KEWEI Edge: Integrated exhaust systems for eco-friendly operation.

Applications of KEWEI’s Metal Heating Machines

- Aerospace: Melt titanium and superalloys for turbine blades.

- Medical: Biocompatible alloys for implants and surgical tools.

- Automotive: Aluminum and magnesium for lightweight EV components.

- Energy: High-temperature alloys for valves and pump bodies.

Case Study: A leading investment casting company reduced energy costs by 30% using KEWEI’s induction melting systems.

How to Choose the Right Metal Heating Machine

- Material Type: Match equipment to your alloys (e.g., titanium, stainless steel).

- Production Scale: Opt for batch or continuous melting systems.

- Energy Efficiency: Look for smart power management and heat recovery.

- Certifications: Ensure compliance with ISO 9001 and industry standards.

Why KEWEI? We offer metal heating machines for investment casting tailored to your needs, backed by 24/7 global support.

FAQs About Metal Heating Machines

Q: What’s the difference between VIM and induction melting?

A: VIM melts under vacuum for zero oxidation; induction uses electromagnetic fields for rapid heating.

Q: Can KEWEI’s furnaces handle reactive metals like titanium?

A: Yes! Our VIM furnaces are designed for titanium, zirconium, and other reactive alloys.

Q: How do I maintain a metal heating machine?

A: Regular coil inspections, crucible replacements, and software updates. KEWEI provides predictive maintenance tools.

Transform Your Melting Process with KEWEI!

✅ Free Trial: Test our metal heating machines with your materials.

✅ Custom Quotes: Tailored solutions for your production scale.

✅ Global Delivery: Installed in 30+ countries with local support.

[Button: Request a Free Consultation →]

Ready to upgrade your foundry? Explore our curated selection of advanced metal casting solutions and request a personalized consultation today!