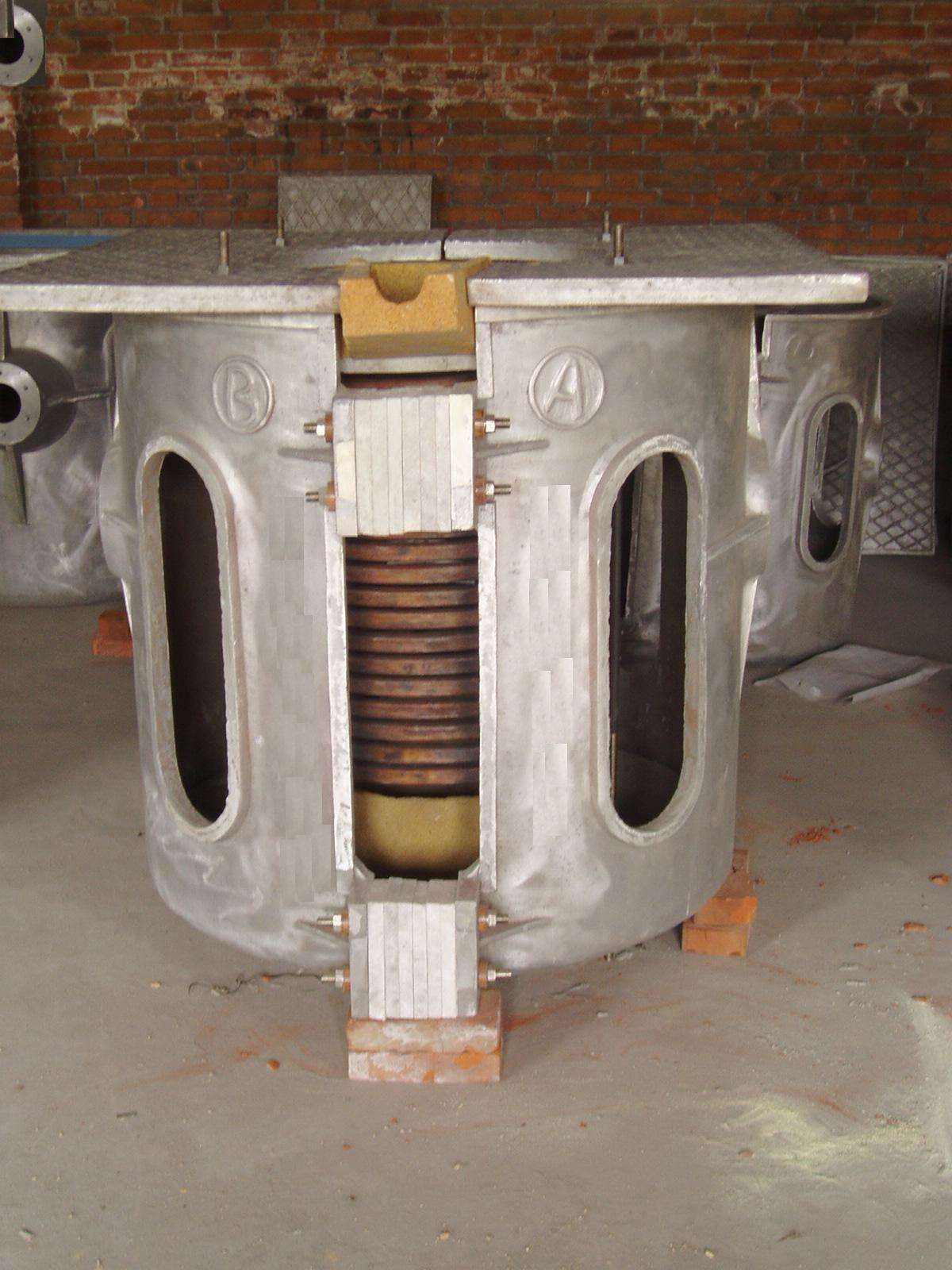

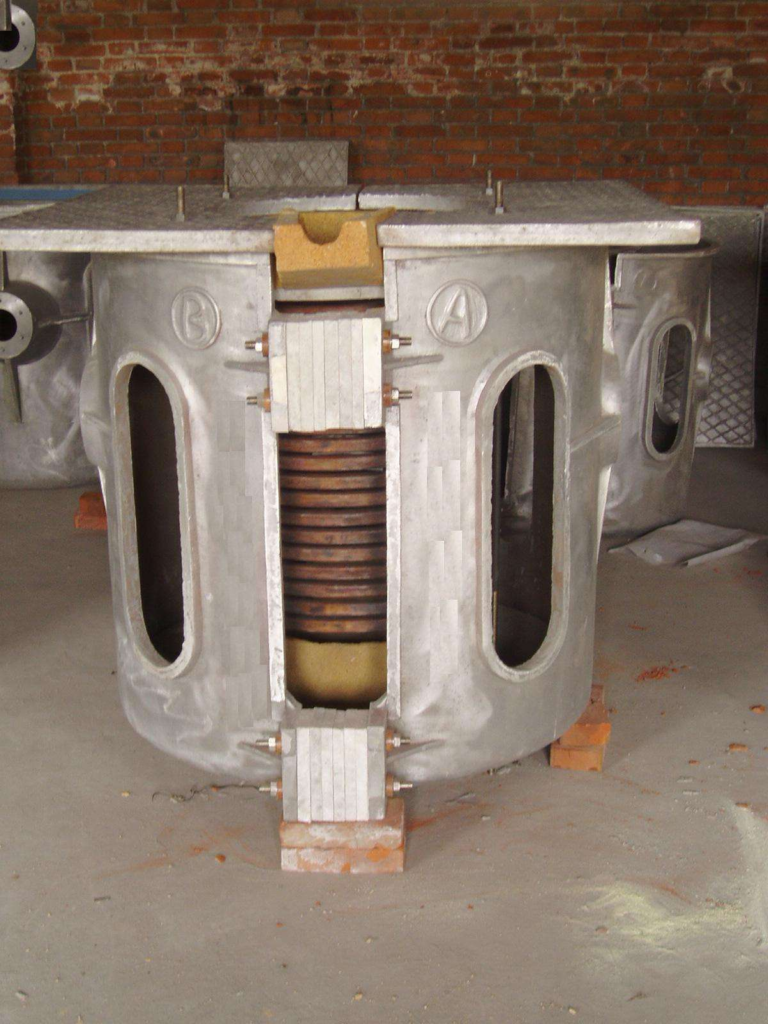

Investment Casting Furnace

KEWEI Powering Precision & Efficiency in Metal Casting

In the investment casting process, the furnace is the heart of metal melting, directly impacting component integrity, energy efficiency, and production costs. KEWEI (formerly KW Casting), a global leader in foundry equipment, engineers investment casting furnace that set new benchmarks for precision and reliability in aerospace, automotive, and energy sectors. Discover how KEWEI’s furnace technology transforms your metal casting outcomes.

1. What is an Investment Casting Furnace?

An furnace melts metals (e.g., steel, titanium, superalloys) to pour into ceramic shell molds. Unlike conventional furnaces, KEWEI’s designs integrate:

- Vacuum/Controlled Atmosphere: Prevent oxidation for cleaner, defect-free melts.

- Temperature Precision: AI-powered controls maintain ±5°C accuracy up to 1800°C.

- Modular Capacity: Ranges from 10kg to 2-ton batches for prototyping to mass production.

Related Keywords: vacuum melting furnace, precision casting furnace, industrial furnace supplier

2. KEWEI Furnace Technology: Why It Leads the Industry

KEWEI’s investment casting furnaces solve critical challenges:

- Energy Savings: Patented insulation reduces power consumption by 25% vs. competitors.

- Ultra-Fast Melting: Induction heating systems cut melt time by 35%.

- Zero Contamination: Graphite-free crucibles ensure pure alloy outputs.

Case Study: A medical device manufacturer reduced scrap rates by 22% using KEWEI’s vacuum furnace for titanium implants.

Related Keywords: KEWEI melting furnace, high-temperature casting furnace

3. Custom Solutions for Diverse Applications

KEWEI tailors furnaces to your needs:

- Aerospace: Vacuum furnaces for nickel superalloy turbine blades.

- Automotive: Rapid-cycle induction furnaces for aluminum EV components.

- Jewelry: Compact furnaces with argon shielding for precious metals.

Related Keywords: custom casting furnace, vacuum induction melting

4. Overcoming Common casting furnace Challenges

- Inconsistent Melts? KEWEI’s real-time thermal monitoring ensures homogeneity.

- High Maintenance Costs? Self-cleaning crucible coatings extend lifespan by 3X.

- Safety Risks? Automated shutoff systems and gas leak detectors protect operators.

Related Keywords: energy-efficient melting

5. Partnering with KEWEI: Beyond Equipment

Choosing KEWEI means investing in full-cycle support:

- Free Energy Audit: Optimize furnace settings for your specific alloys.

- Remote Diagnostics: IoT-enabled systems predict maintenance needs.

- Global Compliance: Furnaces meet CE, UL, and RoHS standards.

Conclusion

A high-performance investment casting furnace is non-negotiable for producing flawless, high-value metal components. With KEWEI’s cutting-edge engineering, industry-leading efficiency, and 24/7 technical support, your foundry gains a competitive edge. Ready to Supercharge Your Casting Line? Contact KEWEI for a free furnace performance analysis!