Casting Investment Machines

Precision, Efficiency & Innovation for Global Foundries

In the precision-driven world of investment casting, the right casting investment machines—from wax injection to final finishing—determine product quality, throughput, and operational costs. KEWEI, a global leader in integrated foundry solutions, delivers end-to-end casting investment machines trusted by the aerospace, automotive, and medical industries. With 20+ years of innovation and ISO 9001-certified engineering, KEWEI empowers foundries to achieve zero-defect production and dominate competitive markets.

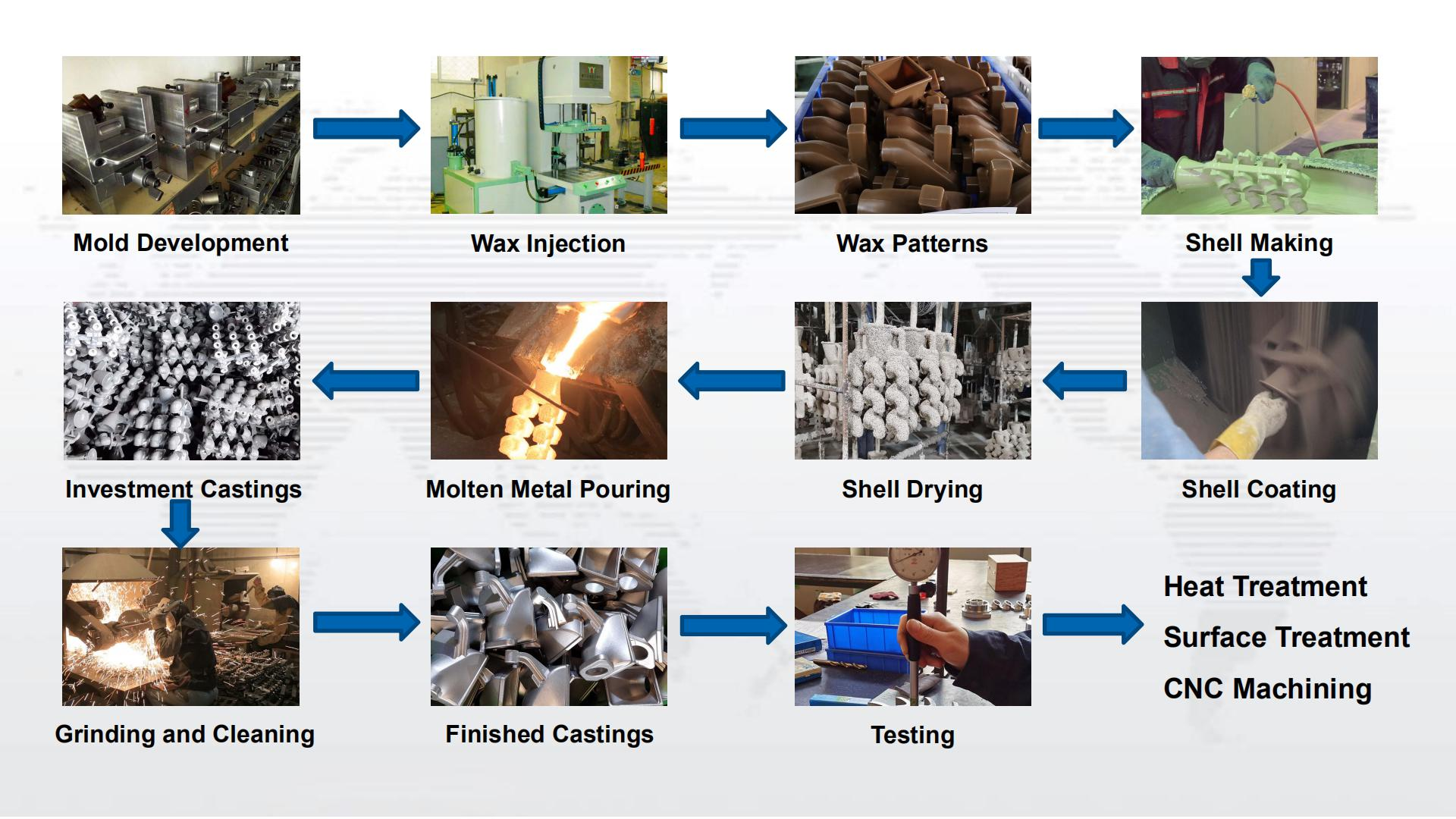

1. Core Machines in KEWEI’s Investment Casting Ecosystem

KEWEI’s casting investment machines cover every critical stage of the process:

A. Wax Pattern Production

- 3D Wax Printers: Achieve ±0.05mm tolerances for complex geometries.

- Automated Wax Injection Machines: Cycle times reduced by 25% with AI-controlled pressure/temperature.

B. Ceramic Shell Building

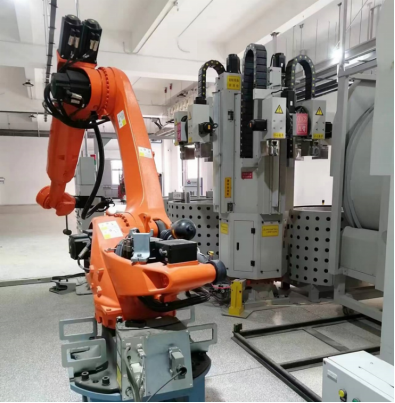

- Robotic Slurry Coaters: 6-axis arms ensure uniform shell thickness (±0.1mm).

- Smart Drying Tunnels: Predictive humidity control cuts curing time by 30%.

C. Melting & Pouring

- Vacuum Induction Furnaces: Melt superalloys (e.g., Inconel 718) up to 1800°C with ±3°C stability.

- IoT-Enabled Pouring Robots: Eliminate turbulence defects via real-time flow monitoring.

D. Post-Casting Finishing

- Automated Knockout Systems: Remove ceramic shells 50% faster.

- 5-Axis CNC Machines: Achieve medical-grade surface finishes (Ra <0.8μm).

Related Keywords: investment casting equipment, precision foundry machines

2. KEWEI’s Competitive Edge in Machine Technology

KEWEI’s casting investment machines redefine industry standards through:

- Energy Efficiency: Patented insulation reduces furnace energy use by 25%.

- AI-Driven Automation: Machine learning optimizes parameters for 99.9% defect-free outputs.

- Scalable Modularity: Expand from prototyping to mass production with plug-and-play units.

Case Study: A European automotive supplier slashed per-unit costs by 22% using KEWEI’s integrated wax-to-CNC line for EV components.

Related Keywords: KEWEI foundry machines, automated casting equipment

3. Industry-Specific Machine Solutions

KEWEI tailors machines to meet stringent demands:

- Aerospace: Vacuum-compatible furnaces and robots for NASA-spec turbine blades.

- Medical: Cleanroom-certified CNC machines for FDA-compliant implants.

- Energy: Corrosion-resistant systems for offshore valve production (API 6A).

Related Keywords: industrial casting machines, custom foundry solutions

4. Solving Foundry Machine Challenges

- High Labor Costs? KEWEI’s robotics handle 80% of repetitive tasks.

- Inconsistent Quality? Real-time sensors adjust processes mid-cycle.

- Slow ROI? Achieve breakeven in <18 months via waste reduction and uptime gains.

Related Keywords: casting machine optimization, foundry cost control

5. Partnering with KEWEI: Beyond Hardware

Choosing KEWEI unlocks:

- Free Process Audit: Identify inefficiencies in your current workflow.

- Smart Factory Integration: Sync machines with ERP/MES via OPC-UA protocols.

- Global Support: 24/7 remote diagnostics and spare parts hubs in 15 countries.

Related Keywords: casting investment machine supplier, turnkey foundry solutions

Conclusion

A KEWEI casting investment machine is more than a tool—it’s a strategic asset built for precision, scalability, and sustainability. With cutting-edge automation, global compliance certifications (AS9100, ISO 13485), and data-driven performance, KEWEI empowers foundries to transform raw materials into high-margin components faster than ever.

Ready to Future-Proof Your Foundry?

Contact KEWEI for a Free Machine Configuration Plan Today!