KEWEI Investment Casting Slurry Suppliers

Precision Formulations for Flawless Shell Molds

Introduction

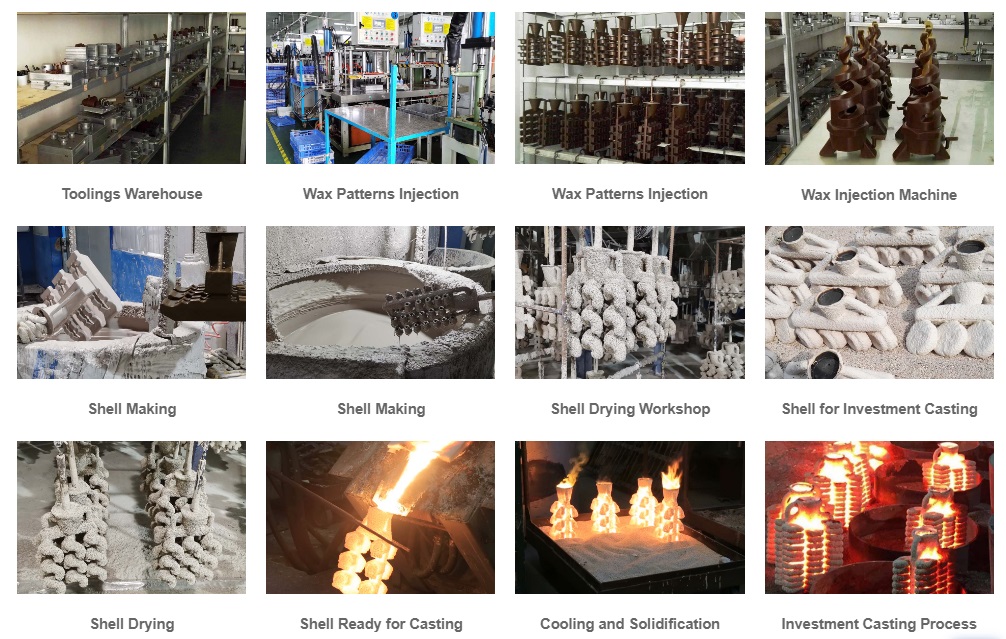

In the investment casting process, the ceramic slurry is the lifeline of mold quality, directly impacting component precision, surface finish, and defect rates. As a top-tier investment casting slurry suppliers, KEWEI (formerly KWM Casting) delivers advanced, industry-specific slurry formulations trusted by aerospace, medical, and automotive giants worldwide. Discover how KEWEI’s R&D-driven blends empower foundries to achieve zero-defect production and dominate competitive markets.

1. The Critical Role of Ceramic Slurry in Investment Casting

Investment casting slurry is a refractory mixture applied to wax patterns to build ceramic shell molds. KEWEI’s formulations excel in:

- Thermal Stability: Withstand temperatures up to 1750°C (alumina-zircon blends).

- Adhesion Control: Proprietary binders prevent layer delamination.

- Surface Finish: Submicron particle sizing for Ra <1.6μm mirror finishes.

Related Keywords: ceramic shell slurry, refractory coating suppliers, precision slurry blends

2. Why Global Foundries Choose KEWEI as Their Slurry Supplier

KEWEI’s investment casting slurries solve industry pain points through:

- Custom Formulations: Tailored viscosity, drying time, and thermal expansion for your alloy.

- Rapid Curing: 20-30% faster drying vs. generic slurries, reducing cycle time.

- ECO Compliance: REACH-certified, low-VOC slurries for sustainable manufacturing.

Case Study: A leading aerospace OEM reduced shell cracking by 90% using KEWEI’s zircon-based slurry for nickel superalloy castings.

Related Keywords: KEWEI ceramic slurry, investment casting material suppliers

3. Industry-Specific Slurry Solutions

KEWEI engineers slurries for extreme applications:

- Aerospace: High-purity alumina slurries for turbine blades (AMS 2175 compliant).

- Medical: Bio-inert zirconia blends for titanium implants (ISO 13485 certified).

- Automotive: Cost-effective silica-alumina slurries for high-volume aluminum parts.

Related Keywords: custom slurry formulations, industrial ceramic coatings

4. Overcoming Slurry-Related Challenges

- Mold Cracking? KEWEI’s graded slurry layers eliminate thermal stress.

- Viscosity Inconsistency? AI-controlled mixing ensures ±5% batch uniformity.

- High Material Waste? Closed-loop recycling systems reduce slurry usage by 25%.

Related Keywords: ceramic shell defects, slurry optimization services

5. Partnering with KEWEI: Beyond Material Supply

Choosing KEWEI unlocks end-to-end support:

- Free Lab Analysis: Audit your current slurry and receive a performance upgrade plan.

- On-Site Training: Slurry preparation and coating best practices.

- Global Logistics: 48-hour emergency delivery to 30+ countries.

Related Keywords: investment casting slurry vendors, foundry material solutions

Conclusion

In an industry where microns matter, KEWEI investment casting slurry suppliers provide the technological edge to transform raw materials into high-value components. With ISO 9001-certified production, 15+ years of metallurgical expertise, and a client-first approach, KEWEI is the trusted partner for foundries aiming to eliminate defects and scale profitably. Ready to Redefine Your Shell Molds? Contact KEWEI for a Free Slurry Sample & Technical Consultation!