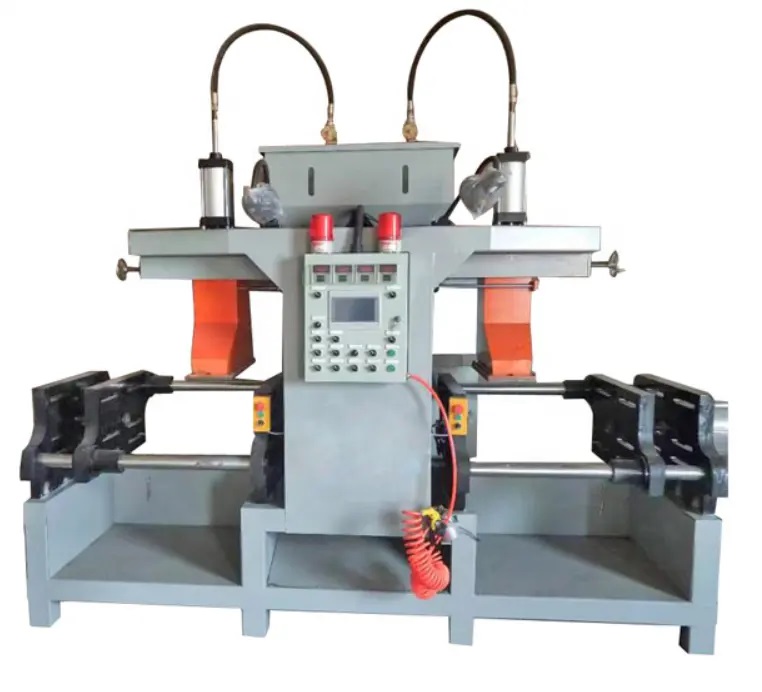

core shooting machine

The Coated Sand Core Shooting Machine uses coated sand as the raw material and operates on the hot core box principle to produce coated sand molds. The core shooting process uses phenolic resin sand, which results in high production efficiency, precise dimensions, smooth surfaces, and the ability to produce castings with complex inner cavities.

The ZH650 Double-Head Core-Shooting Machine is designed to meet the needs of shell shapes and shell cores. Featuring PLC programmable control and adjustable process parameters, this machine also offers automatic mold temperature control. It is ideal for mass-producing small and medium-sized castings with complex shapes. In the ZH650, the coated sand is injected into the core box cavity using high-pressure airflow. The mold is then heated (either electrically or by gas) to 180-240°C, solidifying and forming the sand or shell mold. The molding cycle typically ranges from 30 to 240 seconds, depending on the size of the mold. The result is a smooth product surface that can be used immediately after molding, significantly reducing core-making time and production processes.

The ZH650 machine features a water-cooled shooter, which is integrated for convenience. When modification is needed, the shooter can be split into two parts, improving cost efficiency and expanding the scope of parts that can be used.

Working Principle: The resin sand shell core process involves filling the heated metal core box with shell core sand (phenolic resin sand) for a set time (5-15 seconds). This heat melts the resin near the core box walls, bonding the sand grains to form a plastic shell layer with the desired thickness. After excess sand is removed, the core box continues to heat for 30-90 seconds, solidifying the shell core. Once cooled, the core is ejected, producing a thin-walled shell sand core (5-12mm thick) in just 1-2 minutes.

core shooting machine Product Paramenters

| Item/Model | ZH6510 | ZH6520 | ZH6530 | ZH6540 |

| Pattern size | 540x400mm | 620x280mm | 620x420mm | 700x450mm |

| Clamping stroke | 400mm | 400mm | 400mm | 400mm |

| Max sand core weight | 12kg | 20kg | 18kg | 30kg |

| Shooting pressure | 0.3-0.4Mpa | 0.3-0.4Mpa | 0.3-0.4Mpa | 0.3-0.4Mpa |

| Heat power | 25kw | 25kw | 25kw | 40kw |

core shooting machine Features:

- High Production Efficiency: The core-making process is quick and simultaneous with sand compaction, allowing for rapid core formation—cycles take as little as 10 to 30 seconds.

- High-Quality Sand Cores: The machine can produce precise, smooth sand cores with accurate dimensions, reducing the need for post-casting finishing.

- Eliminates Auxiliary Equipment: The process eliminates the need for core drying furnaces, dryers, core bones, or wax wires, reducing equipment costs.

- Reduces Labor Intensity: Flexible operation with electric heating, automatic temperature control, and easy cleaning, improving workplace conditions and enabling greater automation.

This core-shooting machine streamlines the core-making process, improving efficiency, product quality, and cost-effectiveness in foundry operations.

Daily Maintenance Measures for Core Shooter:

- Check for Leaks: Inspect gas cylinders, gas lines, and valves for leaks, addressing any issues promptly.

- Clean Moving Parts: Regularly clean contact surfaces of moving components such as guide bushes and guide posts to ensure smooth operation.

- Tighten Fasteners: Frequently check all bolts and nuts for looseness and tighten them as needed to maintain equipment stability.

- Daily Cleaning: Clean the equipment at the end of each workday. Perform a thorough cleaning of both the interior and exterior of the machine once a week.

- Maintain Cleanliness of Electrical Components: Keep the electrical cabinet and operator interface clean. Ensure the cabinet door is securely closed when not under maintenance or after set times.

By following these maintenance measures, the core shooter will operate efficiently and reliably, extending its lifespan and minimizing downtime.

Resin Sand Molding Production Line

Foundry Machinery: China Resin Sand Reclamation Casting Machines

The resin sand molding and core-making process utilizes sand mixed with a specific amount of resin glue, which hardens naturally within a certain timeframe at room temperature.

Key Features:

- Self-Hardening Technology: The molding and core sand harden naturally at room temperature, with the hardening rate and final hardness influenced by ambient temperature and humidity.

- Versatile Applications: Ideal for single-piece production, small batch runs, and various medium to large-scale castings.

- Industry Usage: Widely employed in industries such as general machinery, heavy equipment, shipbuilding, locomotive manufacturing, and motorcycles.

Main Configuration of Simple Sand Treatment System

Key Equipment for Simple Furan Resin Sand Treatment:

- Magnetic Separation Belt Conveyor

- Vibration Crusher

- Bucket Elevator

- Eddy Current Regenerator

- Powerful Flow Curtain Winnowing Device

- Garden Vibrating Screen

- Pneumatic Gate

- Double-Arm Continuous Sand Mixer

- Pulse Dust Collector

- Centrifugal Fan for Dust Collector

Resin Sand Molding & Treatment Equipment:

- S25 Series Sand Mixer

- S28 Series Mobile Sand Mixer

- L12 Series Vibration Shakeout Machine

- ZP Series Sand Crusher

- SZJ Series Old Sand Reclaimer

- Sand Cooling Equipment

- Sand Transportation Equipment

- Environmental Protection Dust Removal Equipment

Our Services & Strength

1. Pre-Payment Services:

- Consultation: Free advice on selecting the most suitable machine.

- Custom Design: Tailored designs for individual requirements.

- Factory Visit: Welcoming tours of our manufacturing facility.

2. After-Sales Service:

- On-Site Commissioning: Engineers/technicians dispatched for setup and training.

- Technical Support: Free ongoing support and reasonably priced spare parts.

3. Guarantee Period:

- Duration: One year.

- Coverage: Full support for issues arising from design flaws or machine quality.

- On-Site Repairs: Technician visits covered by the seller for serious issues.

4. Payment Terms:

- 30% deposit upfront.

- 70% balance before delivery.

5. Lead Time:

- In Stock: Delivery in 10–30 days.

- Out of Stock: Delivery in 20–45 days based on order quantity.

Packaging & Shipping

- Packaging: Plastic film wrapping and plywood wooden cases, customized per client request.

- Transport: Secure container shipping for global delivery.

Our streamlined sand treatment solutions ensure efficiency, reliability, and environmental responsibility, catering to the evolving needs of modern foundries.