Lost Foam Casting Production Line

Introduction

Kewei could design the total lost foam Casting production line and all the separate lost foam machines for domestic and abroad customers according to certain workshop condition .and we supply installation,training and after sale service of course.

Technical Specifications

| internal size mording box(mm) | Mording efficiency

(mold/h) |

Annual output | sand processing

capacity (t/h) |

Casting products |

| 1200*1400*320/360mm | 8-10 | 10000 | 5 | Casting rear axle ,brake ,drum,counterweight |

| 1200*1200*250/300mm 1200*1200*400/450mm 1200*1200*600/600mm |

5-7 | 10000 | 5 | wear resistant steel casting,steel gratings |

| 1600*1250*500/300mm 2800*1200*350/450mm |

6 | 10000 | 5-10 | single piece and small batch of castings |

| 1750*1600*650/450mm | 5-10 | 10000 | 5-10 | gray iron castings,counterweight for forkifts,loaders |

| 1000*630*150/150mm 1000*800*150/150mm |

10-15 | 600-1000 | 5 | stainless steel castings such as acid resistant pump impeller |

| 2000*1600*360/310mm | 10 | 30000 | 35-40 | Casting rear axle for trucks |

| 3100*1900*450/450mm 3100*1900*350/550mm |

20 | 50000 | 50 | steel castings for railway parts, bottom, bolater ,side frame |

Features of Lost Foam Casting

High Casting Quality at Low Cost:

Lost foam casting consistently delivers excellent quality while remaining cost-effective. This balance makes it a preferred choice for manufacturers.

Material Versatility:

The process accommodates a wide variety of materials, enabling the production of different sizes without significant limitations.

Precision and Surface Finish:

Achieving high precision and a smooth surface finish is a hallmark of this method. As a result, it reduces the need for extensive cleaning and saves valuable machining time.

Reduced Internal Defects:

This technique significantly minimizes internal defects, leading to a compact and durable casting structure.

Large-Scale Mass Production:

Lost foam casting effectively supports large-scale production, making it ideal for manufacturing numerous components efficiently.

Ideal for Repeated Castings:

It excels in mass-producing identical castings, ensuring consistency across large batches.

Flexible Operation:

The process is highly adaptable, suitable for both manual operations and automated production line controls.

Environmental Compliance:

Importantly, the production line operates in compliance with environmental protection standards, demonstrating a commitment to sustainability.

Improved Working Conditions:

This method enhances the working environment and overall production conditions, reducing labor intensity and energy consumption.

In summary, these features position lost foam casting as a highly efficient and sustainable option for manufacturing complex castings.

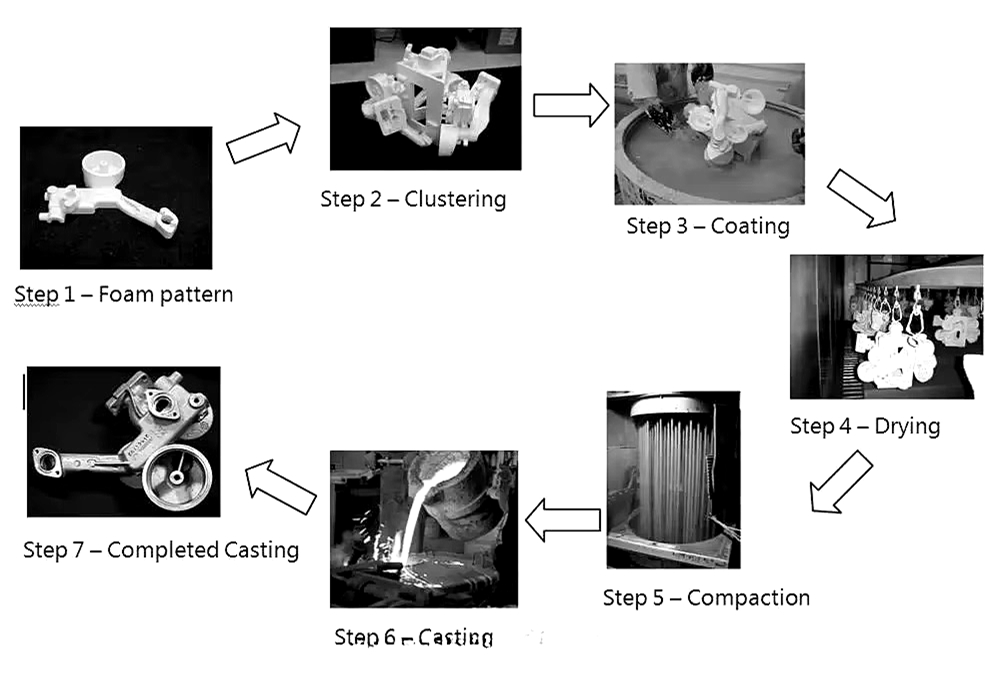

Key Procedural Steps in Lost Foam Casting

Source Material for the Pattern:

Selecting the right material for the pattern is crucial in lost foam casting. For aluminum die castings, manufacturers typically use expandable polystyrene (EPS) with pentane as a blowing agent. In contrast, for cast iron and steel parts, a copolymer made of EPS and EPMMA is the preferred choice.

1. Pattern Material Selection

- Aluminum Die Castings:

Use expandable polystyrene (EPS) with pentane as a blowing agent.

Why: EPS is lightweight and decomposes cleanly at aluminum’s lower melting point (~660°C). - Cast Iron/Steel Parts:

Use a copolymer of EPS and EPMMA (expanded polymethyl methacrylate).

Why: The copolymer withstands higher temperatures (iron: ~1,200–1,500°C; steel: ~1,370–1,500°C) and reduces residue.

2. Pre-Expansion

- Process:

EPS beads are pre-expanded in a fluidized bed dryer using pentane (a volatile hydrocarbon).

Purpose: Increases bead size (typically 20–50x) to achieve target density (e.g., 20–30 kg/m³). - Key Control: Temperature and residence time to ensure uniform expansion.

3. Molding

- Tooling: Pre-expanded beads are blown into a metallic permanent mold using compressed air.

- Bonding: Heated (100–120°C) to fuse beads via steam, forming the foam pattern geometry.

- Pattern Design: Complex geometries are split into sections for easier molding, then assembled post-foaming.

4. Pattern Assembly & Gating

- Cluster Assembly:

Multiple foam patterns are mounted onto a gating system (typically EPS) to form a cluster.

Purpose: Enables simultaneous casting of multiple parts in one pour. - Gating Design: Channels must optimize molten metal flow and minimize turbulence.

5. Coating Application

- Refractory Coating:

Clusters are dipped in a water-based ceramic slurry (e.g., alumina, zirconia) to form a 2 mm coating.

Functions:- Prevents sand erosion during pouring.

- Creates a barrier to reduce gas defects from decomposing foam.

- Enhances surface finish.

- Drying: Coated clusters are dried thoroughly to avoid steam explosions during casting.

6. Mold Preparation

- Sand Compaction:

Coated clusters are placed in a flask, surrounded by unbonded quartz sand (grain size 0.1–0.4 mm).- Sand Raining Feeder: Ensures even distribution.

- Vibrating Table: Compacts sand to 90–95% density for stability.

- Sprue Exposure: Only the gating system’s sprue remains exposed for metal pouring.

7. Casting

- Pouring:

Molten metal is poured into the sprue. The heat decomposes the foam (EPS vaporizes; copolymer may leave minor ash).- Metal Flow: Fills the mold cavity precisely, replicating the foam pattern.

- Gas Management: Decomposition gases (pentane, styrene) vent through the permeable coating and sand.

- Critical Factors:

- Pouring temperature and speed to avoid turbulence.

- Foam degradation rate must match metal front advancement.

8. Demolding & Post-Processing

- Solidification: Metal cools in the sand mold (time depends on part size and alloy).

- Shakeout: Sand is removed via vibration, revealing the casting cluster.

- Cutting: Individual castings are separated from the gating system (e.g., sawing, grinding).

9. Sand Recycling

- Reclamation:

Used sand is cleaned (screening, thermal reclamation) to remove debris and residual coating.

Benefits:- Reduces material costs by 90–95%.

- Environmentally sustainable (minimal waste).