V Process Sand Casting

Innovative Solutions by KEWEI Machinery

In the ever-evolving world of metal casting, V process sand casting has emerged as a revolutionary method known for its efficiency, precision, and environmental friendliness. At KEWEI Machinery, we specialize in providing high-quality equipment for this unique casting process, helping foundries achieve outstanding results while reducing costs.

Whether you’re in the automotive, aerospace, or industrial sector, our V process casting equipment is designed to meet the demands of modern manufacturing with innovative features and unmatched reliability.

What is V Process Casting?

The V process, short for vacuum process, is a cutting-edge sand casting technique that uses vacuum pressure to hold sand molds together without the need for chemical binders. This unique method offers a cleaner, more sustainable approach to casting and is ideal for producing components with complex geometries and smooth finishes.

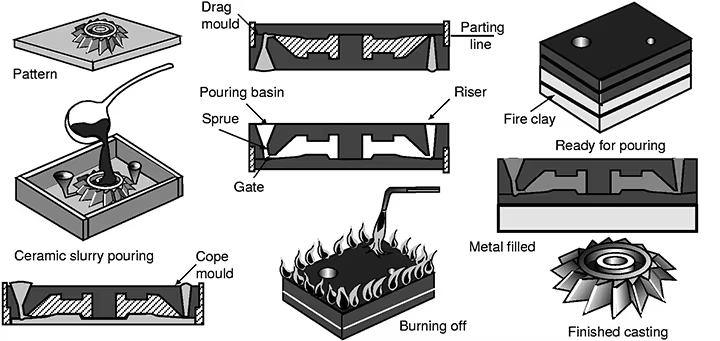

Key Steps in the V Process Casting

- Pattern Preparation: A thin plastic film is placed over the pattern and heated to conform to its shape.

- Vacuum Application: Sand is packed tightly around the film, and vacuum pressure holds the mold together.

- Metal Pouring: Molten metal is poured into the cavity, and the vacuum ensures the mold’s stability.

- Cooling and Removal: Once the metal solidifies, the vacuum is released, and the mold collapses, leaving a high-quality casting.

This process results in fewer defects, smoother surfaces, and greater dimensional accuracy compared to traditional sand casting.

KEWEI Machinery’s V Process Casting Equipment

At KEWEI Machinery, we provide comprehensive solutions for every stage of the V process sand casting workflow. Our advanced equipment ensures efficient production, superior casting quality, and reduced environmental impact.

Core Equipment for Sand Casting

- Vacuum Molding Machines

- High-performance machines for creating accurate and durable sand molds.

- Easy operation with advanced automation features.

- Vacuum Systems

- Energy-efficient vacuum pumps to maintain consistent pressure throughout the process.

- Plastic Film Heating Units

- Reliable units for heating and forming plastic films over patterns with precision.

- Sand Filling and Compaction Systems

- Equipment for evenly distributing and compacting sand, ensuring mold stability.

- Metal Pouring Systems

- Safe and efficient pouring systems to handle molten metal and minimize material loss.

- Post-Casting Equipment

- Tools for removing sand, cleaning, and finishing castings to meet precise specifications.

Advantages of V Process Sand Casting

The casting method offers several advantages over traditional sand casting techniques:

- Smooth Surface Finish: The use of plastic film results in clean, defect-free surfaces.

- Improved Dimensional Accuracy: Vacuum pressure ensures precise mold formation for intricate designs.

- Eco-Friendly Process: The binder-free technique eliminates harmful chemicals, reducing environmental impact.

- Cost Savings: Reusable sand and reduced material waste contribute to lower production costs.

- Minimal Defects: The controlled vacuum environment significantly reduces casting defects such as porosity and shrinkage.

Applications of V Process Casting

The versatility of V process sand casting makes it suitable for a wide range of industries:

- Automotive: Engine blocks, transmission housings, and suspension components.

- Aerospace: Lightweight, high-strength components for aircraft and spacecraft.

- Industrial Machinery: Custom parts for heavy machinery and equipment.

- Construction: Durable metal components for structural applications.

Why Choose KEWEI Machinery for V Process Sand Casting Equipment?

As a trusted manufacturer of foundry solutions, KEWEI Machinery offers unparalleled expertise and support:

- Cutting-Edge Technology

- Our equipment incorporates the latest advancements to ensure precision and efficiency.

- Tailored Solutions

- We design equipment to meet the specific needs of your foundry operations.

- Durability and Reliability

- Built with high-quality materials, our machines deliver consistent performance in demanding environments.

- Comprehensive Support

- From initial consultation to after-sales service, we’re committed to your success.

- Sustainability Focus

- KEWEI Machinery emphasizes eco-friendly designs to promote sustainable manufacturing.

KEWEI Machinery: Your Partner in Foundry Success

If you’re looking to enhance your casting operations, KEWEI Machinery provides the expertise and equipment you need. Our V process sand casting equipment is designed to improve production efficiency, reduce costs, and deliver exceptional casting quality.

Contact us today to explore our full range of solutions and discover how KEWEI Machinery can elevate your foundry operations.

The V process sand casting method is transforming the foundry industry by offering precision, sustainability, and cost efficiency. At KEWEI Machinery, we’re proud to lead the way with innovative equipment that meets the needs of modern foundries.

Explore the possibilities of V process casting and see why KEWEI Machinery is the preferred choice for foundries worldwide.