V-Process Aluminum Casting

Revolutionizing V-Process Technology by Kewei Casting Machinery

At Kewei Casting Machinery, we are dedicated to delivering cutting-edge solutions for modern foundry operations. Our advanced V-Process Aluminum Casting systems combine precision, efficiency, and sustainability, making them the perfect choice for industries seeking superior casting quality and eco-friendly production practices.

What is V-Process Aluminum Casting?

V-Process (Vacuum Process) aluminum casting is an innovative casting method that uses vacuum pressure to form a sand mold without the need for binders. This technique ensures high dimensional accuracy, exceptional surface finishes, and minimal defects, making it an ideal choice for aluminum casting applications.

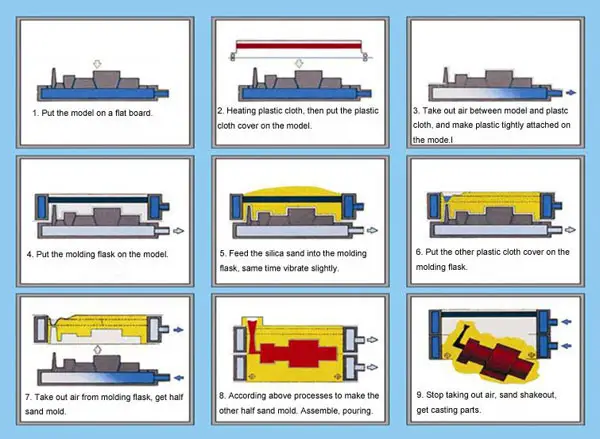

How Does the V-Process Casting Work?

- Vacuum-Sealed Mold Preparation

- A thin plastic film is heated and vacuum-sealed over a pattern to create the mold cavity.

- Sand Compaction

- Dry, unbonded sand is compacted under vacuum pressure, forming a rigid mold.

- Pouring Process

- Molten aluminum is poured into the vacuum-sealed mold cavity. The negative pressure ensures precise filling and minimizes turbulence.

- Solidification and Mold Removal

- Once the aluminum solidifies, the vacuum is released, and the sand collapses for easy casting removal.

Advantages of V-Process Casting:

- High Casting Precision

- Achieve superior dimensional accuracy and smoother surface finishes with reduced machining requirements.

- Cost Efficiency

- No binders or additives are required, reducing material costs and simplifying sand recycling.

- Eco-Friendly Solution

- The process eliminates harmful emissions and promotes green manufacturing practices.

- Improved Casting Quality

- The vacuum-sealed environment minimizes defects such as porosity, shrinkage, and inclusions.

- Extended Mold Life

- The non-contact nature of the process reduces wear and tear on patterns, extending their lifespan.

Applications of V-Process Aluminum Casting

Ihe casting is widely used across various industries:

- Automotive: Engine components, brackets, and lightweight structural parts.

- Aerospace: High-precision aluminum parts with excellent mechanical properties.

- Construction: Architectural elements, brackets, and frames.

- Consumer Goods: Durable aluminum products with aesthetic finishes.

Why Choose Kewei Casting Machinery?

- Innovative Technology: Our V-Process equipment is designed for high precision and efficiency.

- Customizable Solutions: Tailored systems to meet your specific aluminum casting needs.

- Comprehensive Support: From setup to maintenance, we provide end-to-end assistance.

- Sustainability Focus: Align your production with green manufacturing goals using our eco-friendly solutions.

Optimize Your Aluminum Casting Process Today!

Partner with Kewei Casting Machinery to unlock the full potential of V-Process Aluminum Casting. Enhance your casting precision, reduce costs, and promote sustainability with our cutting-edge technology. Contact us now for a tailored solution!