Lost Wax Stainless Steel Casting Equipment

KEWEI Precision Solutions for Complex Parts

For industries demanding corrosion resistance and strength, stainless steel lost wax casting is the gold standard. As a best lost wax stainless steel casting equipment manufacturer, KEWEI delivers cutting-edge machinery trusted by high-quality lost wax stainless steel casting factories worldwide.

Why Partner with the Best Lost Wax Stainless Steel Casting Equipment Suppliers?

- Precision Engineering: Achieve tolerances of ±0.1mm for critical components.

- Material Excellence: Optimized for 304/316L, 17-4PH, and duplex stainless steels.

- Scalability: From prototypes to mass production, meet any demand.

- Global Compliance: Meet ASTM, ISO, and AS9100 standards.

Why KEWEI? We are ranked among the best lost wax stainless steel casting equipment manufacturers for our patented vacuum degassing and ceramic shell technologies.

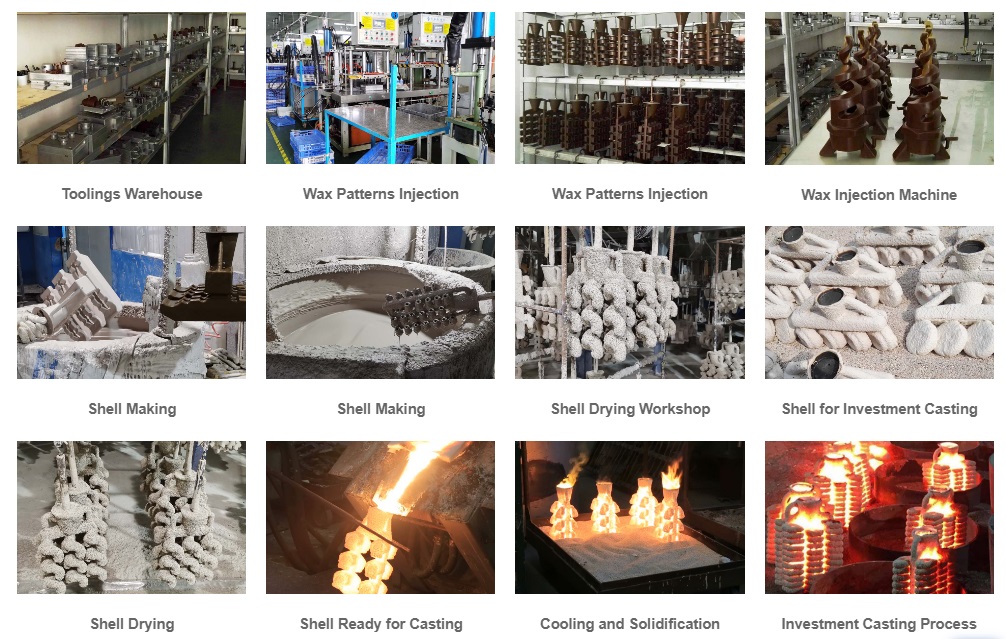

Core Equipment for Lost Wax Casting

- Vacuum Induction Melting (VIM) Furnaces

- Function: Melt stainless steel under vacuum to eliminate impurities.

- KEWEI Edge: Oxygen levels <10ppm for aerospace-grade alloys.

- Precision Wax Injection Systems

- Function: Create intricate wax patterns for complex geometries.

- KEWEI Edge: AI-driven temperature control for ±0.05mm accuracy.

- Automated Ceramic Shell Coating Lines

- Function: Apply uniform ceramic layers for defect-free molds.

- KEWEI Edge: Robotic dipping with real-time viscosity monitoring.

- High-Pressure Vacuum Casting Units

- Function: Pour molten stainless steel with zero porosity.

- KEWEI Edge: Vacuum levels ≤30mbar, ideal for medical and marine applications.

Applications of KEWEI’s Equipment in Top Industries

- Medical: Surgical instruments, implants from high-quality lost wax stainless steel casting suppliers.

- Aerospace: Turbine blades supplied to best lost wax stainless steel casting companies like GE Aviation.

- Oil & Gas: Corrosion-resistant valves and pumps for extreme environments.

- Luxury Goods: Precision-crafted watch cases and jewelry.

Case Study: A best lost wax stainless steel casting factory in Germany reduced scrap rates by 40% using KEWEI’s VIM furnaces.

How to Choose the Best Lost Wax Stainless Steel Casting Equipment Manufacturer

- Certifications: Verify ISO 9001 and industry-specific credentials.

- Technical Support: Ensure 24/7 global service and spare parts availability.

- Sustainability: Look for energy-efficient designs and recycling systems.

- Industry Reputation: Partner with high-quality lost wax stainless steel casting manufacturers with proven track records.

Why KEWEI? We are a best lost wax stainless steel casting equipment supplier with 20+ years of expertise serving Fortune 500 companies.

FAQs About Lost Wax Casting Equipment

Q: What makes stainless steel lost wax casting unique?

A: It combines corrosion resistance with complex geometries, ideal for medical and aerospace parts.

Q: How do I find the best lost wax stainless steel casting suppliers?

A: Evaluate their technology, certifications, and client portfolios—like KEWEI’s partnerships with Siemens and Stryker.

Q: Can KEWEI’s equipment handle large orders?

A: Yes! We support best lost wax stainless steel casting factories with 10,000+ monthly output.

Join the Leaders in Stainless Steel Casting!

✅ Free Equipment Demo: See KEWEI’s machines in action.

✅ Customized Quotes: Tailored solutions for your production scale.

✅ Global Installation: Expert support in 30+ countries.

Ready to upgrade your foundry? Explore our curated selection of advanced metal casting solutions and request a personalized consultation today!