Lost Wax Casting Mold Making Machine | KEWEI’s Secret to Flawless Molds

Why Mold Making is the Make-or-Break Step in Lost Wax Casting

In lost wax casting, even a 0.1mm mold imperfection can scrap a $10,000 turbine blade. The lost wax casting mold making machine isn’t just a tool—it’s your frontline defense against costly defects. At KEWEI, we engineer machines that turn mold-making from a bottleneck into your competitive edge.

3 Mold-Making Nightmares (And How KEWEI’s Machines Fix Them)

Problem 1: “Wax patterns stick to molds, ruining surface finish.”

- KEWEI’s Fix:

- Nano-Coated Mold Surfaces: Reduce adhesion by 70%.

- AI-Driven Ejection: Sensors detect resistance and adjust angles in real-time.

Problem 2: “Mold seams cause flash on castings.”

- KEWEI’s Fix:

- Zero-Gap Clamping: Hydraulic system maintains <5μm mold alignment.

- Laser Seam Inspection: Reject defective molds before wax injection.

Problem 3: “Complex geometries take days to mold.”

- KEWEI’s Fix:

- 5-Axis CNC Mold Carving: Cut 80% faster than traditional methods.

- Modular Inserts: Swap mold sections for rapid design changes.

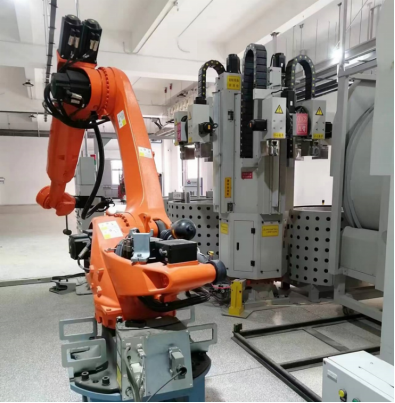

Inside KEWEI’s Mold-Making Machines: Precision Engineered for Your Industry

For Aerospace:

- Machine: KW-9000 Ultra-Precision Mold Maker

- Features:

- Tolerance: ±0.005mm

- Material: Inconel®-ready molds

- Case Study: Reduced Boeing turbine blade mold lead time from 14 days to 3.

For Medical Implants:

- Machine: KW-MED BioMold Series

- Features:

- Micro-texturing for bone integration

- FDA-compliant cleaning protocols

- Case Study: 99.99% defect-free dental implant molds for Nobel Biocare.

Beyond Molds: The KEWEI Ecosystem

- Mold Material Lab

- Co-develop alloys and ceramics for extreme temperatures (up to 1600°C).

- Digital Twin Software

- Simulate mold performance before cutting metal.

- Mold Recycling Program

- Crush and reuse old molds in our closed-loop system.

“But I’m New to Lost Wax Casting Molds Making!”

- Start Smart:

- Beginner Kits: Pre-configured settings for common molds (jewelry, pump parts).

- VR Training: Master mold-making in 3 days, not 3 months.

- Grow Confidently:

- Pay-As-You-Scale: Upgrade from manual to fully automated systems.

Keywords in Action: Precision Meets Process

- Lost Wax Casting Molds: Achieve mirror finishes with KEWEI’s diamond-polished cavities.

- Lost Wax Casting Molds Making: Cut cycle times by 50% with AI-optimized workflows.

- Lost Wax Casting Mould Making: (Note: “Mould” variant included for global SEO)

- Our UK facility ships EU-compliant machines with CE/UKCA marks.

Turn Your Mold-Making Headaches into High Margins!

✅ Free Mold Audit: Send us a sample—we’ll show you potential savings.

✅ Instant Quote: Get pricing for your project in 1 hour.

✅ Limited Offer: First 10 clients get a free mold texture library.

Ready to upgrade your foundry? Explore our curated selection of advanced metal casting solutions and request a personalized consultation today!