Investment Molding Casting Machine

KEWEI’s All-in-One Precision Solution

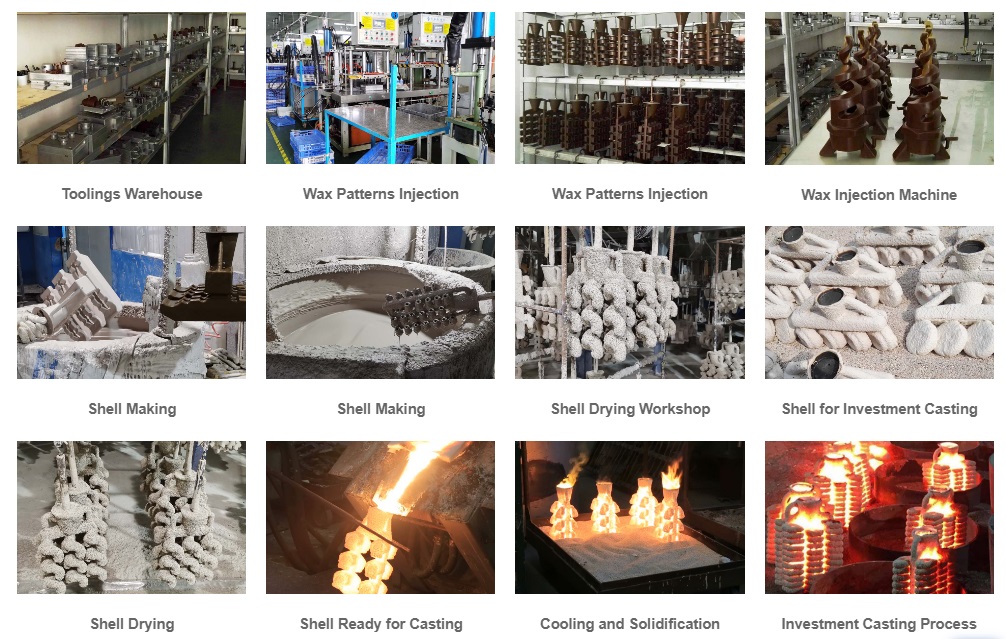

The investment molding casting machine is the backbone of precision casting, bridging the gap between wax patterns and flawless metal parts. At KEWEI, we’ve engineered a machine that integrates wax injection, ceramic coating, and vacuum casting into one seamless system—revolutionizing how foundries operate.

Why Choose KEWEI’s Investment Molding Casting Machine?

- All-in-One Design: Combine wax molding and metal casting in a single machine.

- Ultra-High Precision: Achieve tolerances as tight as ±0.05mm.

- Energy Efficiency: Reduce energy consumption by 40% with smart power management.

- Scalability: From prototypes to mass production, adapt to any demand.

Key Features of KEWEI’s Investment Molding Casting Machine

- Integrated Wax Injection System

- Function: Create precise wax patterns with ±0.03mm accuracy.

- KEWEI Advantage: Multi-cavity molds with IoT-enabled temperature control.

- Automated Ceramic Coating Unit

- Function: Apply uniform ceramic layers for defect-free shells.

- KEWEI Advantage: Robotic slurry dipping with real-time viscosity monitoring.

- Vacuum Casting Chamber

- Function: Pour molten metal under vacuum for porosity-free castings.

- KEWEI Advantage: Vacuum levels ≤30mbar, ideal for aerospace and medical parts.

- AI-Driven Process Control

- Function: Monitor and optimize every step, from wax injection to metal solidification.

- KEWEI Advantage: Predictive maintenance reduces downtime by 50%.

Applications of KEWEI’s Investment Molding Casting Machine

- Aerospace: Turbine blades, engine housings, and structural components.

- Medical: Biocompatible implants and surgical instruments.

- Automotive: Lightweight EV components with complex geometries.

- Energy: High-temperature alloy parts for turbines and pumps.

Why Choose KEWEI: Our machines are trusted by industry leaders for delivering mission-critical components with unmatched precision.

Benefits of Choosing KEWEI’s Investment Molding Casting Machine

- End-to-End Efficiency: Eliminate handling between wax molding and metal casting.

- Material Versatility: Cast stainless steel, aluminum, titanium, and superalloys.

- Cost Savings: Reduce labor, energy, and material waste.

- Future-Ready: Upgradeable with new features via software updates.

FAQs About Investment Molding Casting Machines

Q: How does KEWEI’s machine handle complex geometries?

A: Our 5-axis wax injection and vacuum casting systems ensure flawless reproduction of intricate designs.

Q: Can I use this machine for small-batch production?

A: Yes! KEWEI’s modular design allows quick changeovers for low-volume runs.

Q: What support does KEWEI provide after purchase?

A: Installation, operator training, maintenance plans, and 24/7 technical support.

Ready to Revolutionize Your Foundry with KEWEI?

✅ Free Demo: Watch our machine in action at your facility.

✅ Custom Quote: Get pricing tailored to your production needs.

✅ Fast Delivery: Minimize downtime with quick shipping.

Ready to upgrade your foundry? Explore our curated selection of advanced metal casting solutions and request a personalized consultation today!