KEWEI Investment Casting Ceramic Shell Moulding

recision, Durability & Sustainability

Introduction

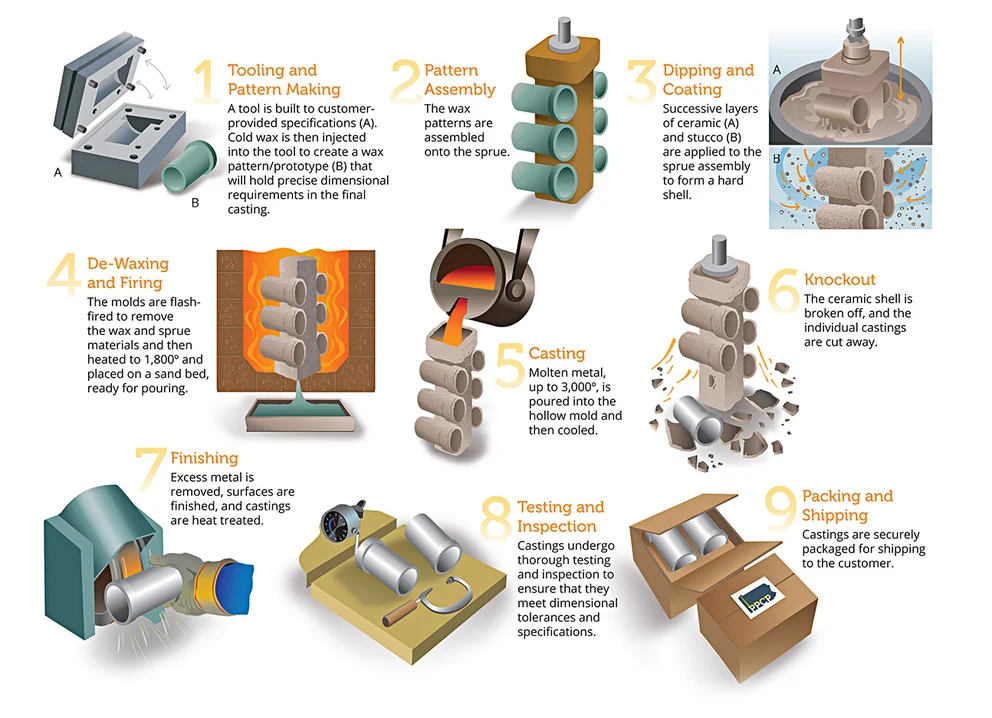

In investment casting, the ceramic shell moulding process is the backbone of producing high-integrity metal components with complex geometries. KEWEI, a global leader in precision foundry solutions, pioneers Investment Casting Ceramic Shell Moulding technologies that combine cutting-edge materials, AI-driven automation, and decades of expertise. Trusted by aerospace, medical, and energy industries, KEWEI’s ceramic shells ensure flawless castings, reduced costs, and compliance with AS9100, ISO 13485, and API standards.

1. The Science Behind Ceramic Shell Moulding

KEWEI’s ceramic shell moulding process involves layering refractory materials onto wax patterns to create ultra-stable molds. Key innovations include:

- High-Purity Materials: Alumina-zircon blends withstand 1700°C+ for superalloys like Inconel 718.

- Graded Layer Design: Optimized thermal expansion coefficients prevent cracking during dewaxing and casting.

- AI-Controlled Slurry Coating: Robotic arms ensure ±0.1mm thickness uniformity.

Related Keywords: ceramic shell process, investment casting shell materials

2. KEWEI’s Investment Casting Ceramic Shell Moulding Advantages

KEWEI’s ceramic shell moulding solutions solve critical industry challenges:

- Zero Porosity Defects: Nanoparticle-modified slurries reduce gas entrapment by 50%.

- Rapid Drying Cycles: Infrared-assisted curing cuts shell production time by 30%.

- Eco-Friendly Formulations: REACH-compliant binders lower VOC emissions by 40%.

Case Study: A turbine blade manufacturer achieved 99.9% defect-free castings using KEWEI’s ceramic shells for nickel superalloys.

Related Keywords: KEWEI ceramic shell technology, precision shell moulding

3. Industry-Specific Applications

- Aerospace: Thin-wall shells for turbine blades (AMS 2175 compliant).

- Medical: Bio-inert shells for titanium implants (ASTM F136).

- Energy: Corrosion-resistant shells for offshore valve components (API 6A).

Related Keywords: ceramic shell for investment casting, industrial shell moulding

4. Solving Common Investment Casting Ceramic Shell Moulding Issues

- Shell Delamination? KEWEI’s adhesion promoters ensure inter-layer bonding.

- Surface Roughness? Submicron stucco particles achieve Ra <1.6μm finishes.

- High Material Waste? Closed-loop slurry recycling reduces costs by 25%.

Related Keywords: ceramic shell defects, investment casting optimization

5. Partnering with KEWEI: Full-Cycle Support

Choosing KEWEI unlocks:

- Free Shell Analysis: Audit your current process and receive a performance report.

- Smart Automation Kits: Upgrade legacy systems with AI-driven robotic coaters.

- Global Logistics: Just-in-time delivery to 30+ countries with MIL-SPEC packaging.

Related Keywords: ceramic shell moulding supplier, foundry process solutions

Conclusion

The KEWEI ceramic shell moulding process redefines precision, efficiency, and sustainability in investment casting. With 20+ years of R&D, 50+ patents, and a client base spanning aerospace to medical sectors, KEWEI empowers manufacturers to transform raw materials into high-value components—flawlessly and profitably.

Ready to Elevate Your Shell Moulding?

Contact KEWEI for a Free Shell Sample & Technical Consultation!