How to Choose the Right Investment Casting Machine

Expert Guide by Kewei

Selecting the right investment casting machine is critical for achieving precision, efficiency, and ROI. Whether you’re producing aerospace components or medical implants, this guide will help you make an informed decision.

Key Factors to Consider When Choosing a Machine

- Production Requirements

- Volume: Small-scale (prototyping) vs. large-scale (mass production).

- Complexity: Simple shapes vs. intricate designs (e.g., turbine blades).

- Material Compatibility

- Wax Injectors: Ideal for detailed wax patterns.

- Ceramic Coating Systems: Suitable for high-temperature alloys.

- Vacuum Furnaces: Essential for porosity-free titanium parts.

- Automation Level

- Manual Machines: Lower cost, suitable for startups.

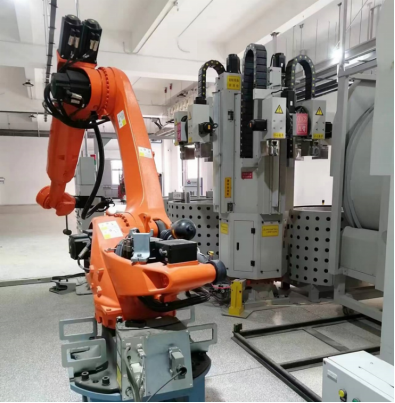

- Fully Automated Systems: Higher efficiency, ideal for large foundries.

- Budget Constraints

- Compare investment casting machine prices to find the best fit.

- Consider long-term ROI, not just upfront costs.

Types of Investment Casting Machines

| Machine Type | Best Use Case | Key Features |

|---|---|---|

| Wax Injectors | Creating precise wax patterns. | Temperature control, multi-cavity molds. |

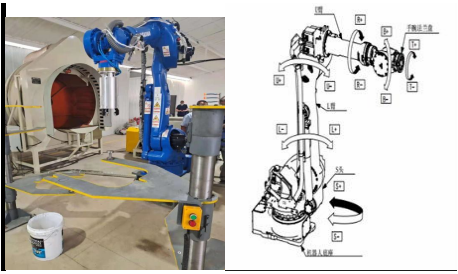

| Ceramic Coating Systems | Applying uniform ceramic shells. | Robotic arms, adjustable drying cycles. |

| Vacuum Casting Furnaces | Producing defect-free metal components. | High-temperature range, vacuum sealing. |

| Complete Casting Lines | End-to-end production for large volumes. | Integrated automation, IoT monitoring. |

Step-by-Step Selection Process

- Define Your Needs

- Identify part size, material, and production volume.

- Research Suppliers

- Compare brands like LK Group, Yizumi, and global leaders.

- Request Quotes

- Use our investment casting machine price guide to compare costs.

- Evaluate Support Services

- Check for installation, training, and maintenance options.

- Test Before Buying

- Request a demo or trial run to assess performance.

Common Mistakes to Avoid

- Overlooking Maintenance Costs: Factor in spare parts and servicing.

- Ignoring Future Needs: Choose scalable machines for growth.

- Focusing Only on Price: Balance cost with quality and features.

FAQs About Choosing Casting Machines

Q: What’s the difference between manual and automated machines?

A: Manual machines are cheaper but slower; automated systems offer higher efficiency and precision.

Q: Can one machine handle multiple materials?

A: Some machines are versatile, but specialized equipment often delivers better results.

Q: How do I know if a supplier is reliable?

A: Check certifications (ISO 9001), customer reviews, and after-sales support.

Still Unsure Which Machine is Right for You?

✅ Free Consultation: Get personalized recommendations from our experts.

✅ Competitive Quotes: Compare prices from top suppliers.

✅ Fast Delivery: Minimize downtime with quick shipping.

[Button: Speak to an Expert Now]

Check our detailed price guide for investment casting machines.