Foundry Casting Machinery

Casting is a fundamental process in modern machinery manufacturing. As a metal heat-processing technology, casting has become highly advanced in our country. Casting machinery refers to all equipment used to melt metal into a liquid state that meets specific requirements, pour it into molds, and produce castings with the desired shape, size, and properties after cooling, solidification, and cleaning. This foundry Casting Machinery is also known as casting equipment.

Foundry Casting Machinery Classification

Casting machinery is typically classified based on the molding method and is generally divided into ordinary sand casting and special casting.

- Ordinary Sand Casting includes:

- Wet Sand Casting

- Dry Sand Casting

- Chemical Hardening Sand Casting

- Special Casting can be further categorized based on the molding materials used:

- Natural Mineral Sand and Stone Casting: Examples include investment casting, shell casting, negative pressure casting, mud casting, solid casting, and ceramic casting.

- Metal Material Casting: Examples include metal mold casting, centrifugal casting, continuous casting, pressure casting, and low-pressure casting.

Casting Equipment

- Sand Mixer

A sand mixer is casting equipment used to mix molding sand or core sand. It evenly blends old sand, new sand, binders, and auxiliary materials to create uniform molding sand. - Sand vibration Falling Machine

This equipment uses vibration and impact to separate molding sand from the casting. Sand falling machines can utilize different vibration sources, including mechanical, electromagnetic, and pneumatic systems. - Shot Blasting Machine

Shot blasting machines use high-speed projectiles, propelled by a shot blaster, to clean or strengthen casting surfaces. They can simultaneously remove sand, cores, and clean the casting. - Core Making Machine

Core-making machines are used to produce sand cores for casting. Based on the process, these machines are classified into:- Self-hardening sand core machines

- Hot core-making machines

- Coated sand core-making machines

- Cold core-making machines

- Molding Machine

Molding machines are designed to create sand molds by filling and compacting loose molding sand into sandboxes. - Pouring Machine

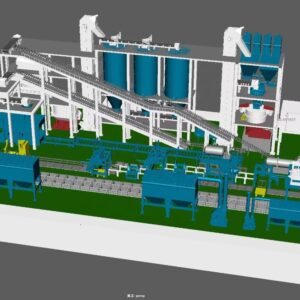

A pouring machine introduces liquid metal into casting molds efficiently and accurately. - Self-Hardening Sand Molding Production Line

This production line includes:- Continuous sand mixer

- Vibrating table

- Transport trolley

- Surface drying kiln

- Flip mold opening machine

- Box closing machine

Foundry Casting Machinery Development

The level of casting machinery is directly linked to the overall development of the casting industry. Currently, the domestic casting machinery industry in China faces challenges in achieving the nation’s goal of transitioning from a “large casting country” to a “strong casting country”. This journey requires significant effort and innovation.

While the industrial output value of China’s casting machinery industry continues to reach new milestones, the CNC (Computer Numerical Control) adoption rate remains low.

- Export Perspective:

- Annual export value: Approximately US$100 million.

- Export volume: Around 1,500 units, with CNC products accounting for less than 20%.

- Casting machinery exports contribute only a small proportion to the overall machine tool industry, reflecting the industry’s relatively low technical level.

- Import Perspective:

- Annual import value: Exceeds US$200 million.

- Import volume: Around 500 units annually.

- Instability in imports and exports persists, with sharp declines observed over consecutive years, demonstrating the industry’s vulnerability to external factors.

Foundry Casting Machinery Future Development Trends

The development of casting machinery equipment in China is rapidly evolving, with ongoing adjustments to align with future industry demands. Moving forward, the domestic foundry machinery industry will focus on the following four major directions:

- High-Quality, High-Efficiency, and Green Development

- Prioritizing sustainable production with advanced, environmentally friendly, and efficient machinery.

- Expanded Equipment Capacity and Broader Application

- Enhancing production capacity while expanding the scope of application across diverse casting processes and industries.

- Digitalization, Automation, and Intelligence

- Accelerating the adoption of advanced technologies:

- Informatization of design and R&D

- Digitalization of equipment

- Intelligent production processes

- Networking of operations and management

- Fully integrating computer technology to achieve real-time data processing, automation, and remote management.

- Accelerating the adoption of advanced technologies:

- Establishment of Expert and Information Systems

- Developing expert systems and advanced information processing tools.

- Leveraging the Internet for remote capabilities, including:

- Off-site research

- Remote demonstrations

- Remote control and diagnosis

These four trends represent the inevitable path for the future development of China’s foundry machinery and equipment industry. By embracing innovation, integration, and sustainability, the sector will play a pivotal role in advancing the foundry industry.

With continued investments and focus, China’s domestic foundry machinery industry is poised to embark on a healthy, sustainable, and stable growth trajectory, bringing the nation closer to achieving its vision of becoming a global leader in casting technology.

Why Choose KEWEI’s Foundry Casting Machines?

KEWEI is a global leader in manufacturing Investing casting machines and sand casting foundry equipment. Here’s what sets our solutions apart:

- Precision Engineering

KEWEI’s machines are designed to deliver exceptional accuracy, ensuring each casting meets the most stringent specifications. - Advanced Automation

Our lost foam casting machinery integrates advanced automation systems to streamline operations, reduce human error, and boost production efficiency. - Durability and Reliability

KEWEI’s equipment is built to withstand the harsh conditions of foundries, offering long-term reliability and minimal maintenance requirements. - Customizable Solutions

We provide tailored solutions to match the specific needs of your foundry, whether it’s upgrading your existing systems or setting up a complete lost foam casting equipment line.

Trust KEWEI to deliver solutions that transform your operations and help you stay ahead in the competitive foundry industry. Contact us today to learn more about our products and services, and let’s build a stronger future together.